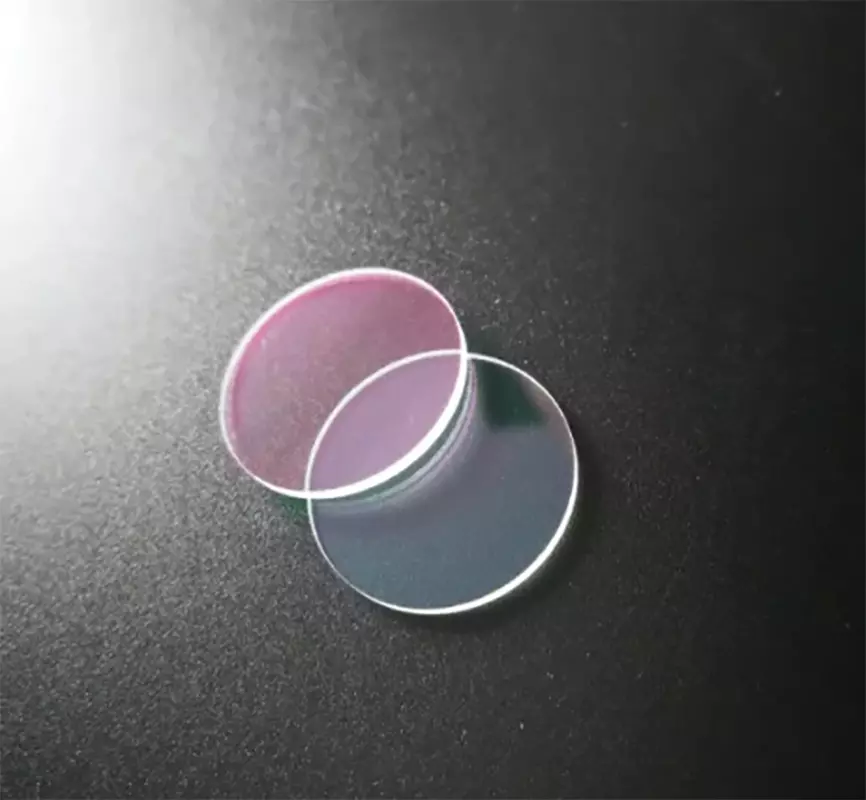

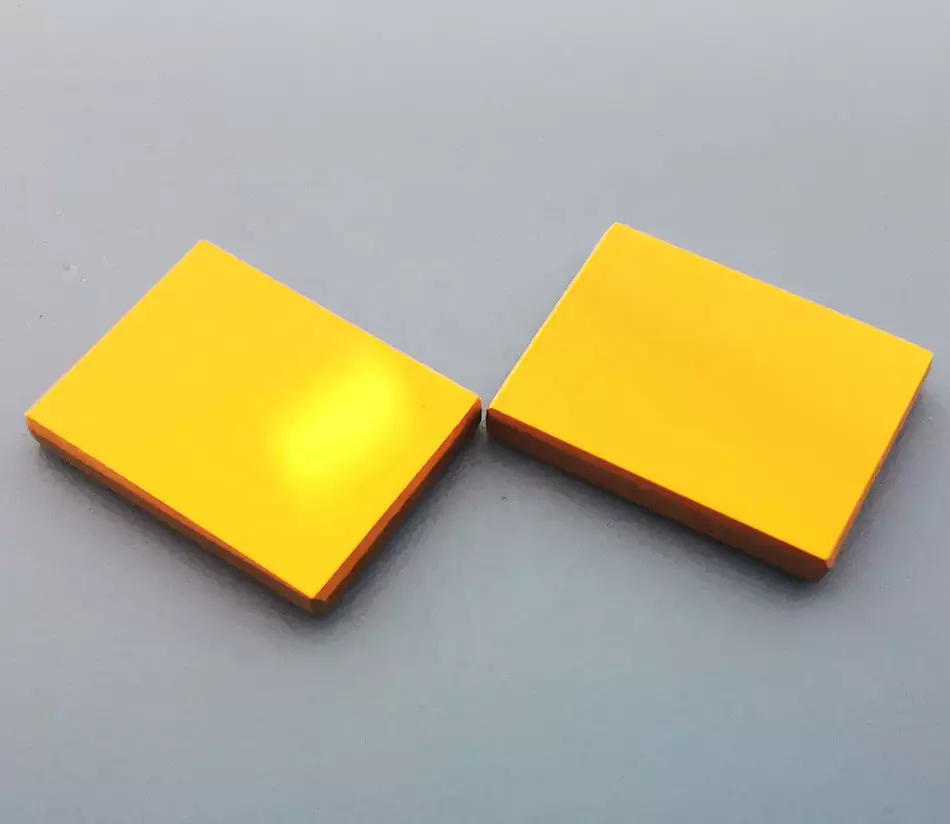

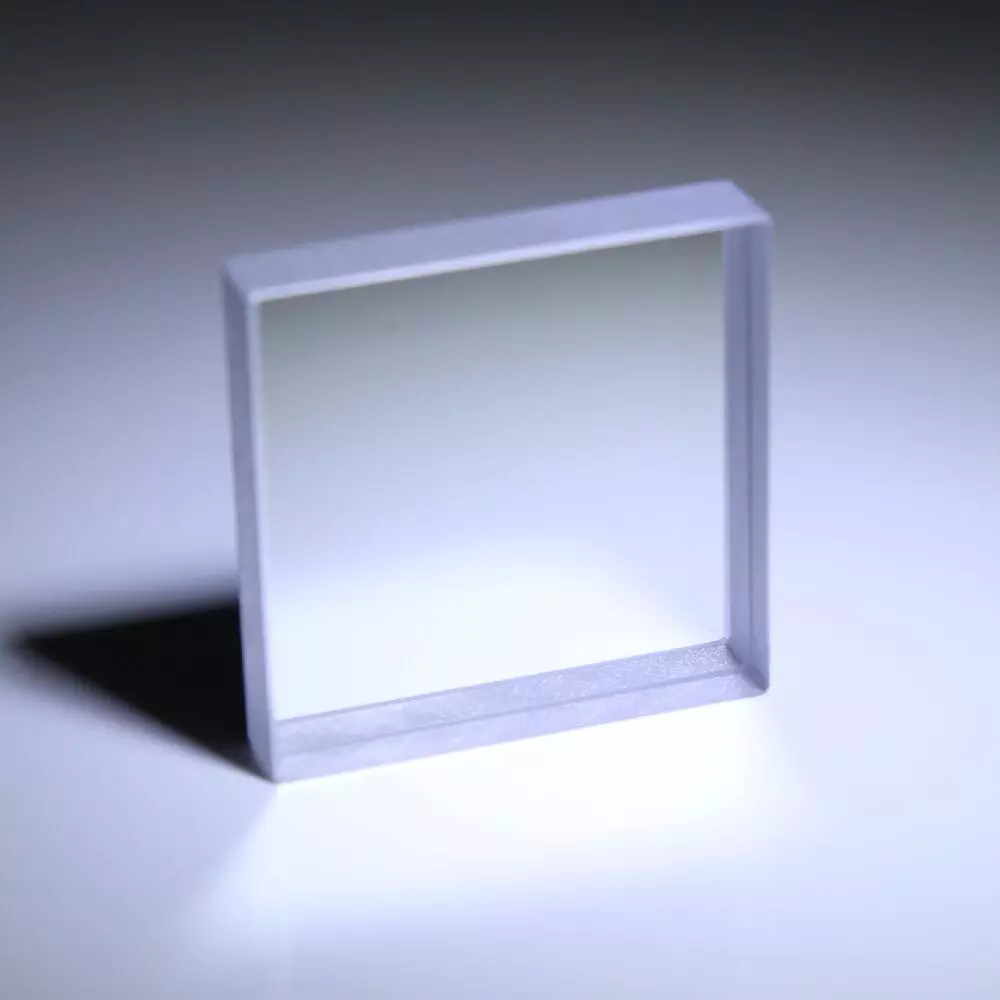

An optical mirror is a high-precision reflective component designed to manipulate light across various applications, from laser systems to advanced scientific research. These mirrors ensure minimal distortion and high efficiency, making them indispensable in optics, photonics, and industrial processes. Manufactured with specialized coatings, optical mirror glass delivers superior reflectivity and durability, essential for high-energy environments.

Durable Optical Mirrors for Laser & Scientific Applications

High-quality optical mirrors serve critical roles in fields like spectroscopy, astronomy, and biomedical imaging. Their ability to reflect specific wavelengths with minimal loss makes them vital for beam steering, laser cavities, and interferometry setups. The performance of an optical mirror glass depends on factors such as substrate material, coating type, and surface accuracy.

Industries utilizing optical mirrors include:

- Laser Technology – Ensuring precise light reflection in laser cutting, medical lasers, and optical communication.

- Scientific Research – Used in telescopes, microscopes, and spectrometers for accurate optical measurements.

- Industrial & Aerospace – Integrated into alignment systems, robotics, and navigation equipment for high-precision applications.

Types of Optical Mirror Glass

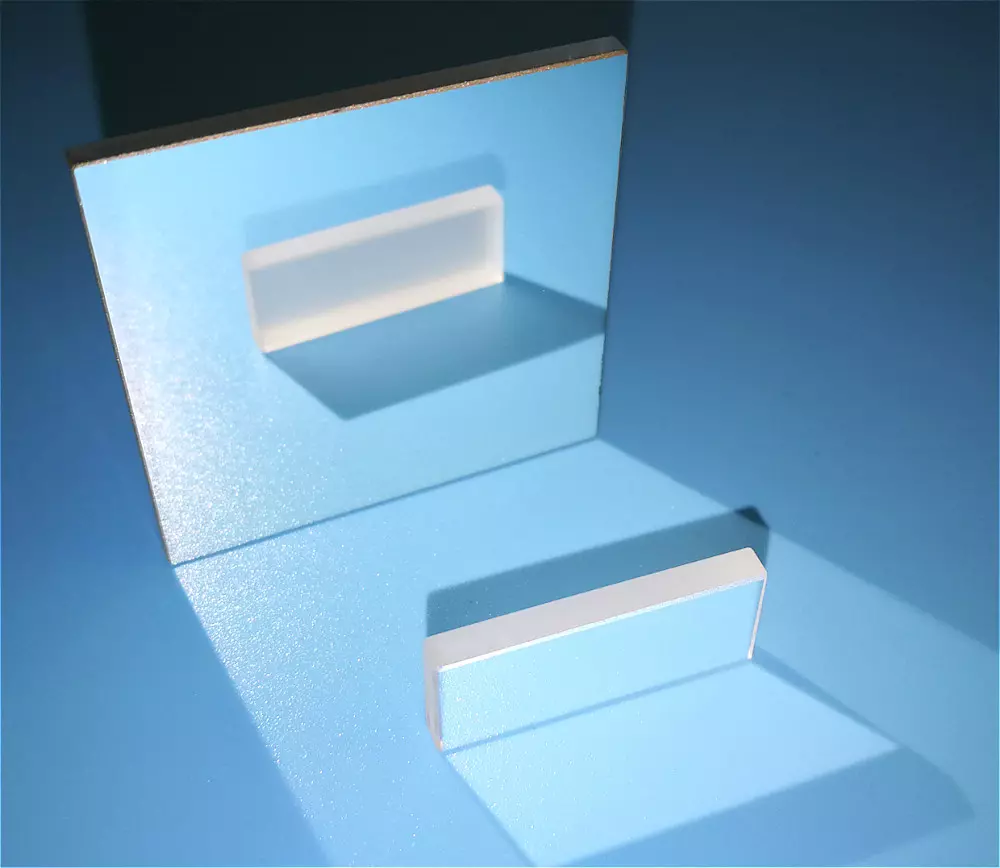

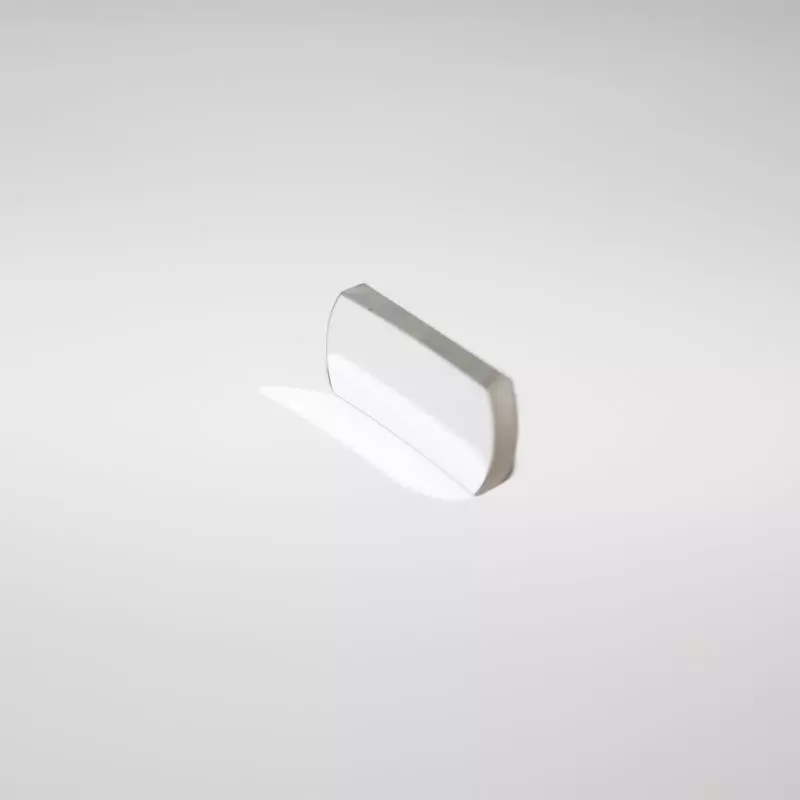

Several categories of optical mirror glass exist, each tailored to specific operational needs:

- Metal-Coated Mirrors – Feature aluminum, silver, or gold coatings to optimize reflectance across UV, visible, or infrared spectra.

- Dielectric Mirrors – Offer high reflectivity for narrow or broadband wavelengths, commonly used in laser optics.

- Cold & Hot Mirrors – Designed to reflect visible light while transmitting infrared or vice versa, ideal for thermal management applications.

Choosing the Right Optical Mirror

Selecting an optical mirror depends on reflectivity requirements, environmental conditions, and application-specific parameters. Important considerations include:

- Coating Durability – Ensuring longevity and resistance to oxidation or damage from high-power lasers.

- Substrate Material – Fused silica, borosilicate, and other glass types offer varying thermal stability and mechanical strength.

- Surface Quality – A lower surface roughness reduces scattering and enhances performance in high-precision systems.

By choosing the appropriate optical mirror glass, users can optimize optical efficiency, reduce energy losses, and achieve superior results in their optical setups.

We offer fast and secure shipping of optical mirrors across the USA and Europe, ensuring timely delivery for laser technology, scientific research, and industrial applications. Our trusted logistics network guarantees safe handling and efficient transit, so you receive high-quality optical mirror glass without delays. Experience hassle-free international shipping with our reliable service.

Our Ordering Process

Send us your request with detailed specifications

Receive a commercial offer with terms and costs

After your approval, we handle manufacturing, quality control, and shipping

📦 Shipping

3-5 days in EU, from 10 days to USA

💳 Payment methods

Cash, Bank Transfer, Cards (Visa, Mastercard, Amex, Discover) and PayPal

💬 Questions?

Contact us via WhatsApp, phone, live chat or email