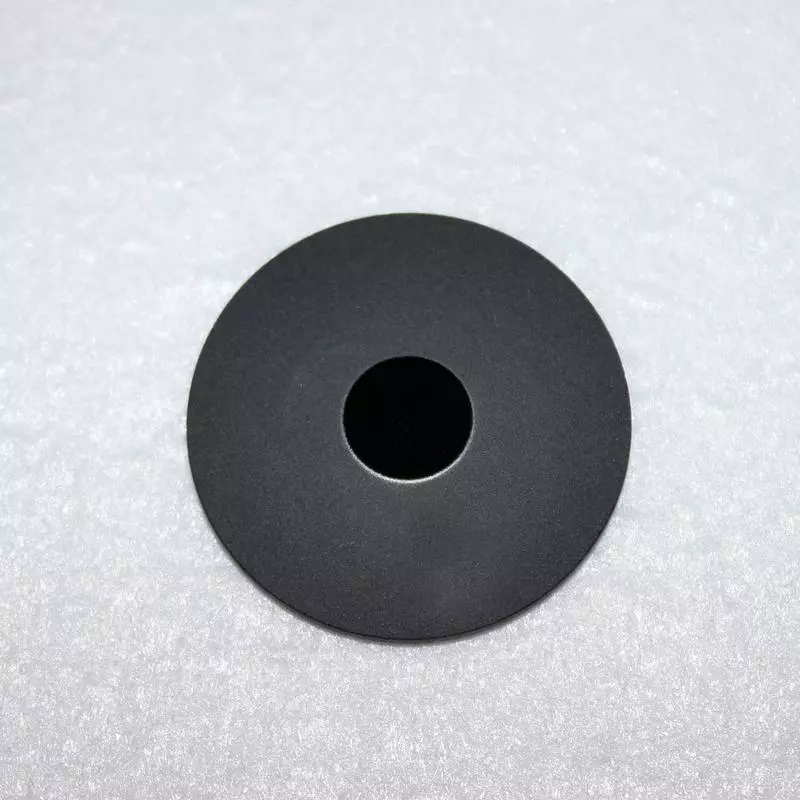

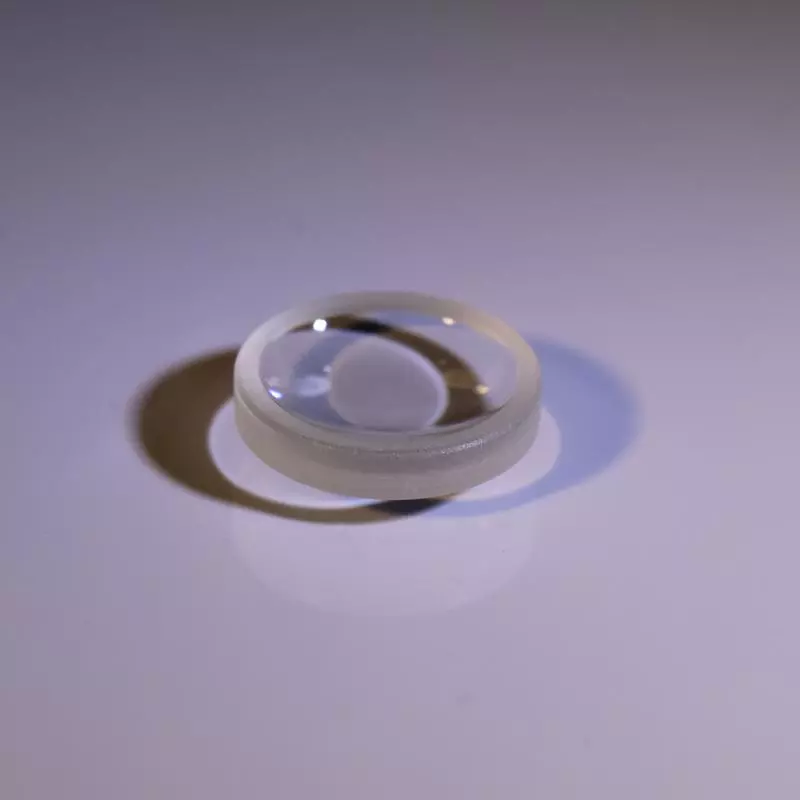

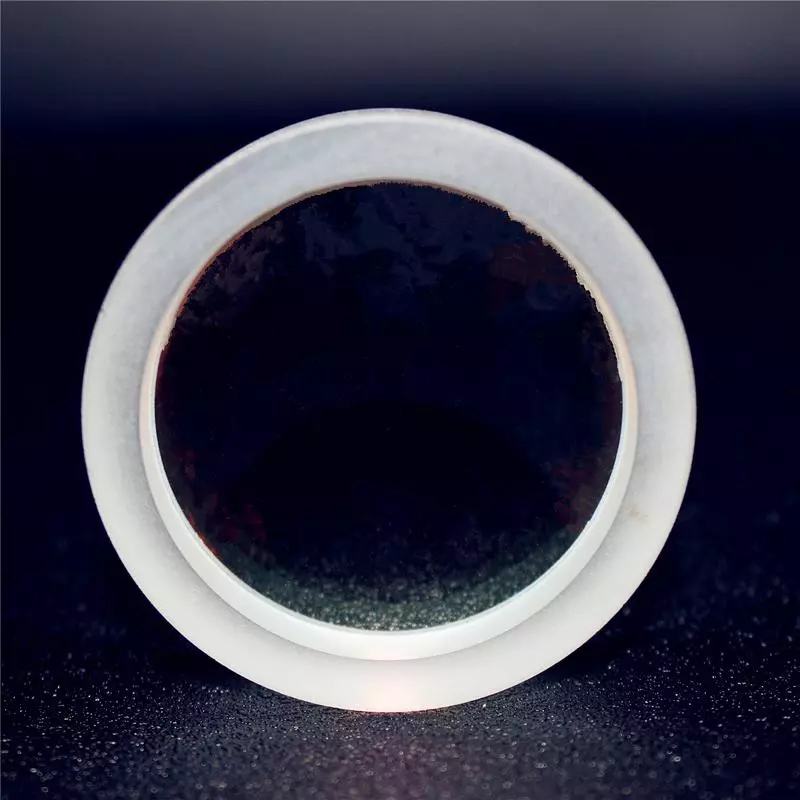

Spherical lens

A spherical lens is a crucial optical component that plays a fundamental role in various imaging and light-focusing applications. Whether in microscopes, cameras, telescopes, or medical devices, these lenses ensure precision and optimal clarity. With a curved surface designed to refract and direct light, spherical lenses come in diverse configurations to meet specific optical requirements. Understanding their characteristics, benefits, and applications allows for better utilization in scientific, industrial, and commercial fields.

Spherical Lenses for Superior Optical Performance & Clarity

What is a Spherical Lens?

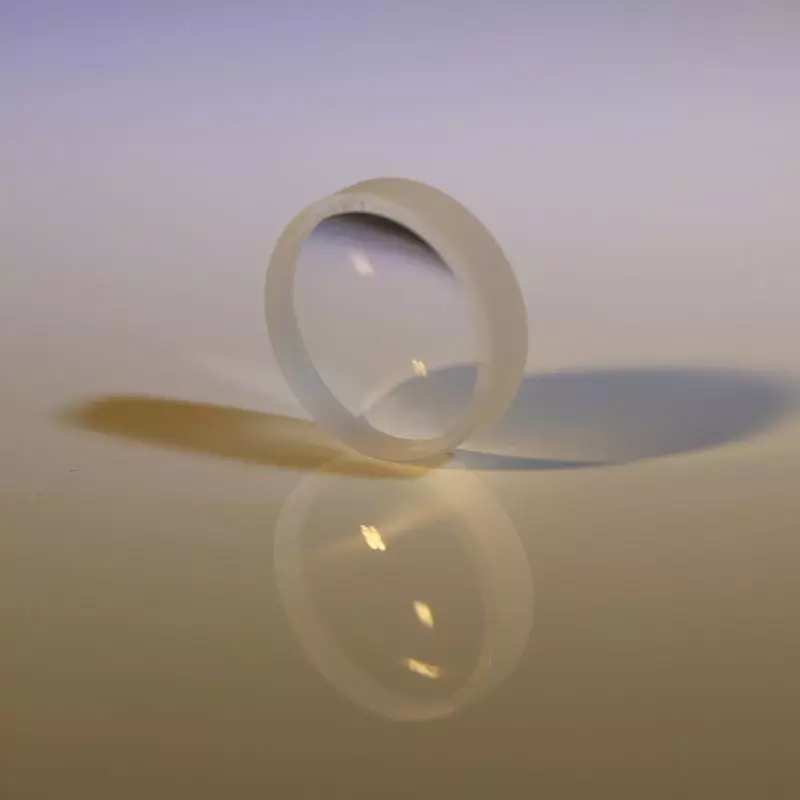

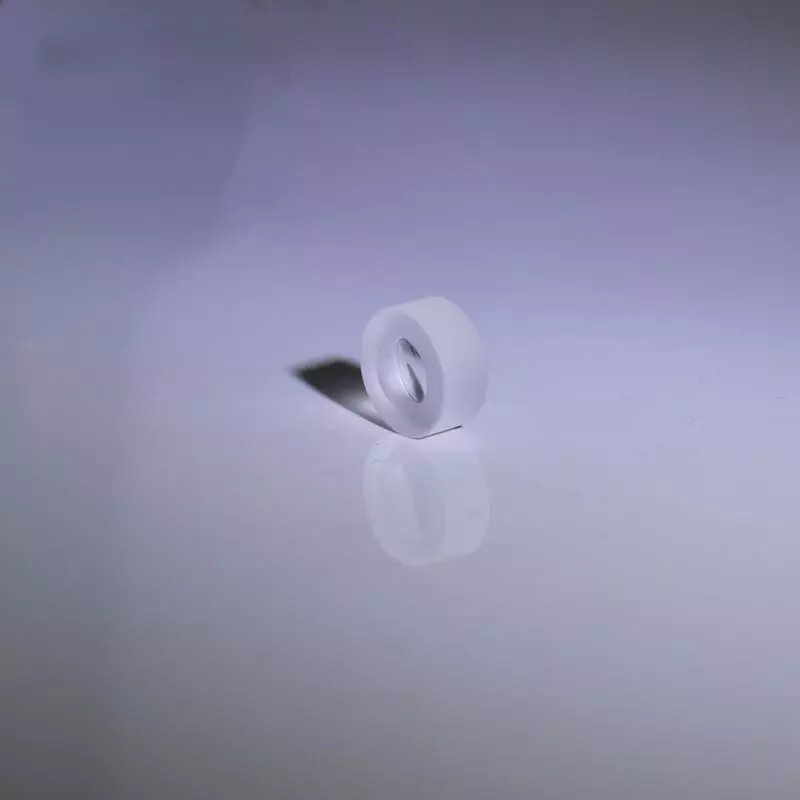

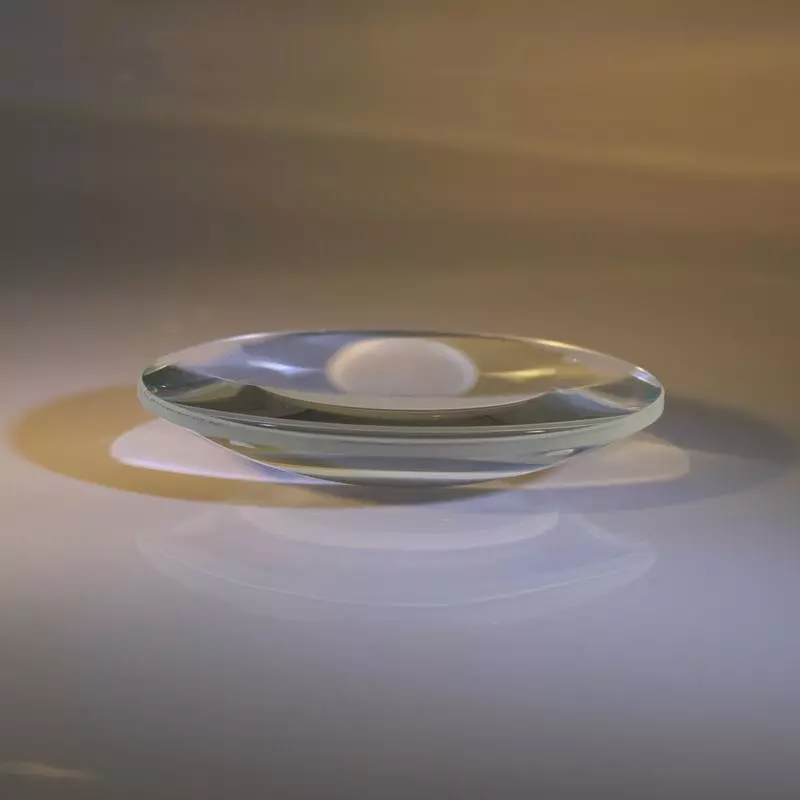

A spherical lens is an optical element with a surface curvature that forms a part of a sphere. These lenses can be convex (converging) or concave (diverging), depending on how they manipulate light. They are commonly manufactured from optical glass, fused silica, or high-grade polymers to enhance performance across different wavelengths.

- Convex Lenses: These lenses are thicker at the center and help in converging light rays to a focal point, making them essential for magnification and focusing systems.

- Concave Lenses: With edges thicker than the center, concave lenses diverge light rays, often used in beam expansion and vision correction applications.

The curvature and refractive index of the material influence how light bends, impacting the efficiency of optical systems.

Advantages of Using Spherical Lenses

The widespread adoption of spherical lenses across various industries is due to their numerous advantages:

- Versatile Optical Design – Suitable for various imaging systems, including medical imaging, laser optics, and consumer electronics.

- Cost-Effectiveness – Easier to manufacture compared to aspherical lenses, making them a practical choice for high-volume production.

- Efficient Light Manipulation – Ability to control and focus light effectively, improving image resolution and clarity.

- Wide Range of Materials – Manufactured using high-precision optical glass, quartz, or polymers to meet specific optical and thermal requirements.

- High Customizability – Available in different focal lengths, diameters, and coatings to optimize performance in specialized applications.

Applications of Spherical Lenses in Various Industries

1. Photography and Imaging Systems

Spherical lenses are integral to cameras, microscopes, and telescopes, where they help in achieving accurate image formation. High-quality lens coatings reduce distortions and enhance image sharpness, making them indispensable in professional photography and videography.

2. Medical and Scientific Instruments

Microscopes and endoscopes utilize spherical lenses to enhance magnification and provide clear, detailed views in medical diagnostics and laboratory research.

3. Laser Systems and Optical Communication

Precision optical components like spherical lenses are vital in laser focusing, beam shaping, and fiber-optic communication. Their role in directing and managing light paths ensures efficiency in high-tech applications.

4. Automotive and Aerospace Technologies

Advanced vehicle vision systems, HUDs (heads-up displays), and aerospace navigation rely on precisely engineered spherical lenses to enhance visibility and performance.

5. Industrial and Manufacturing Sectors

Laser cutting, 3D printing, and quality inspection systems incorporate spherical lenses to ensure precision in high-accuracy tasks.

Material Selection for Optimal Lens Performance

Choosing the right material significantly impacts the effectiveness of spherical lenses. Key materials include:

- BK7 Glass: A widely used optical glass offering high transmission and low dispersion, ideal for visible and near-infrared applications.

- Fused Silica: Provides excellent thermal stability and resistance to UV radiation, making it suitable for high-energy laser applications.

- Acrylic and Polycarbonate: Lightweight and durable options for consumer and industrial applications where cost and impact resistance matter.

Anti-Reflective and Protective Coatings

To maximize efficiency, many spherical lenses are coated with specialized layers:

- Anti-Reflective (AR) Coatings: Minimize reflection and enhance light transmission, crucial for high-performance optical systems.

- UV and IR Coatings: Protect lenses from harmful radiation while improving durability.

- Scratch-Resistant Coatings: Increase longevity, especially in outdoor and industrial environments.

How to Choose the Right Spherical Lens

Selecting the most suitable spherical lens depends on several factors:

- Application Needs: Determine whether a convex or concave lens best suits the intended use.

- Material Properties: Consider factors such as temperature resistance, optical clarity, and environmental conditions.

- Coating Requirements: Opt for coatings that enhance durability and optical performance in specific conditions.

- Size and Focal Length: Ensure compatibility with the optical system for optimal focusing and image clarity.

A spherical lens is an indispensable component in numerous optical systems, offering reliability, precision, and adaptability. Whether in imaging, medical technology, laser optics, or industrial applications, these lenses provide superior light control and enhanced performance. By choosing the right material, coatings, and design, spherical lenses can significantly improve optical systems’ efficiency and longevity.

We offer fast and secure shipping of spherical lenses across the USA and Europe, ensuring timely delivery for imaging, medical, and industrial applications. Our trusted logistics network guarantees safe handling and efficient transit, so you receive high-quality optical components without delays. Experience hassle-free international shipping with our reliable service.

Our Ordering Process

Send us your request with detailed specifications

Receive a commercial offer with terms and costs

After your approval, we handle manufacturing, quality control, and shipping

📦 Shipping

3-5 days in EU, from 10 days to USA

💳 Payment methods

Cash, Bank Transfer, Cards (Visa, Mastercard, Amex, Discover) and PayPal

💬 Questions?

Contact us via WhatsApp, phone, live chat or email