ZnSe, Ge, Si, BaF for laser machine

When it comes to laser technology, selecting the right optical materials is essential for optimal performance and efficiency. ZnSe, Ge, Si, BaF for laser machine applications offer superior optical properties, making them indispensable in modern laser systems. These materials are widely used in industrial cutting, medical procedures, and scientific research. Their ability to transmit, focus, and manipulate laser beams with high precision makes them an excellent choice for professionals seeking maximum accuracy and durability.

ZnSe, Ge, Si, BaF Optical Materials for Laser Machines

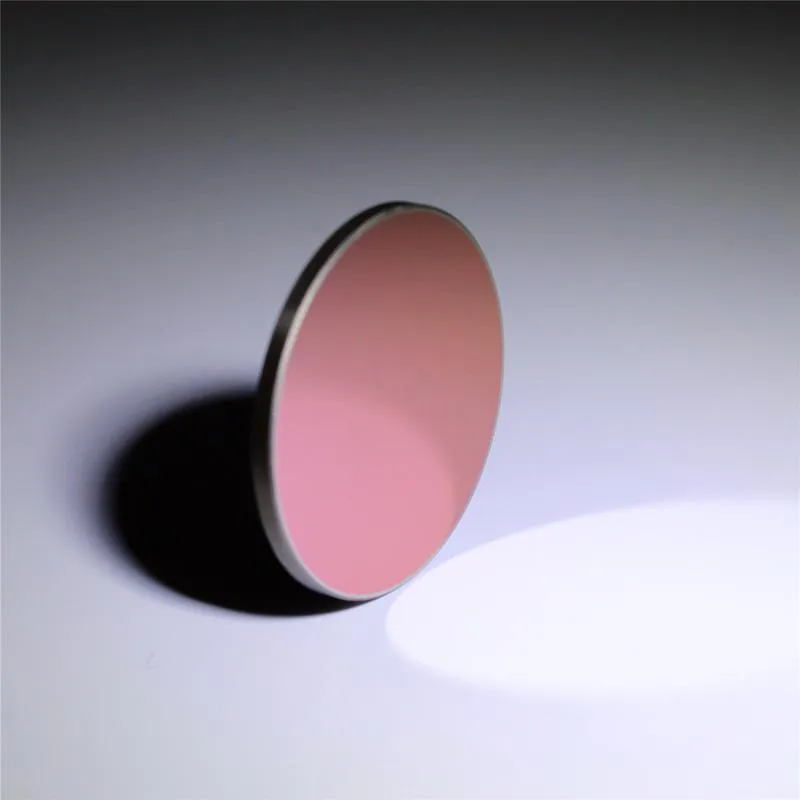

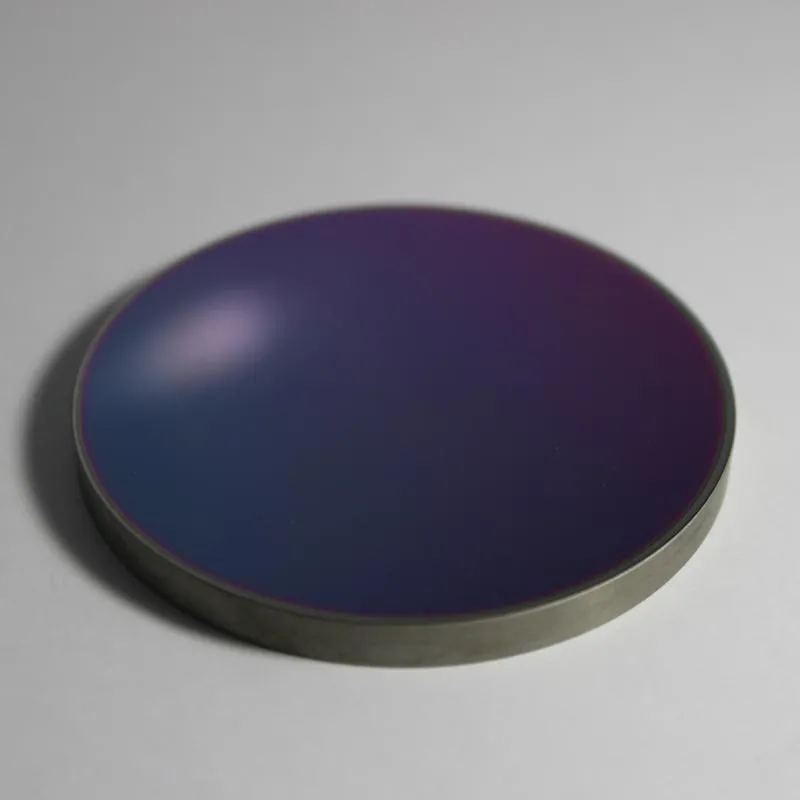

Zinc Selenide (ZnSe) lenses are among the most sought-after optical components in laser systems. With outstanding infrared (IR) transmission and a low absorption coefficient, ZnSe lenses are perfect for CO2 laser applications. The growing ZnSe lenses market is driven by increasing demand for high-powered laser cutting and engraving systems. These lenses ensure minimal energy loss and precise beam focusing, improving the efficiency and accuracy of laser machinery.

Advantages of ZnSe lenses:

- High transmittance in the 8-12 µm IR range

- Low absorption, reducing thermal effects

- Durable and resistant to harsh environments

- Ideal for CO2 laser cutting and engraving machines

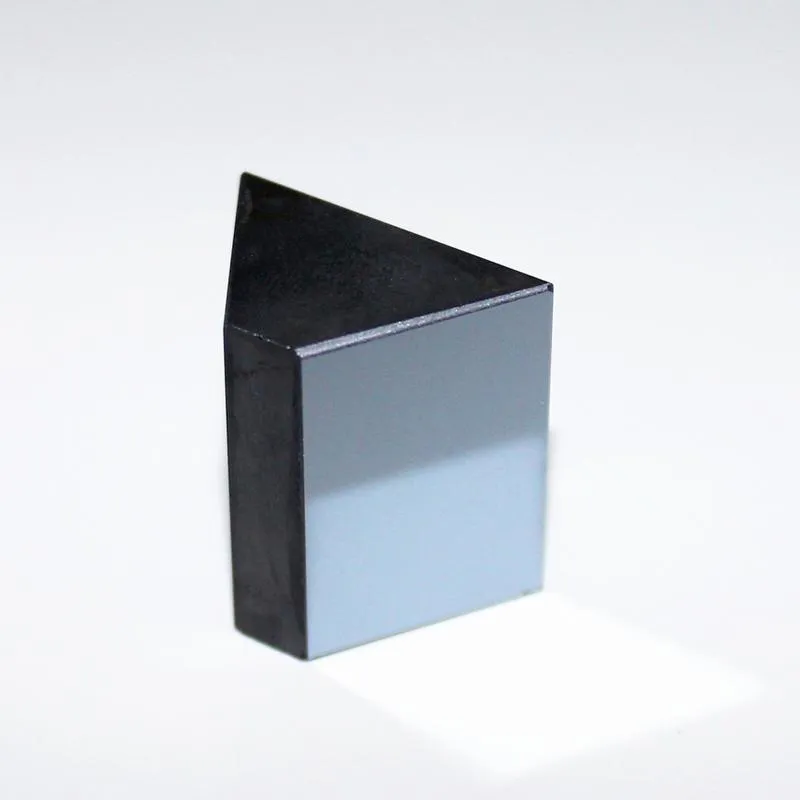

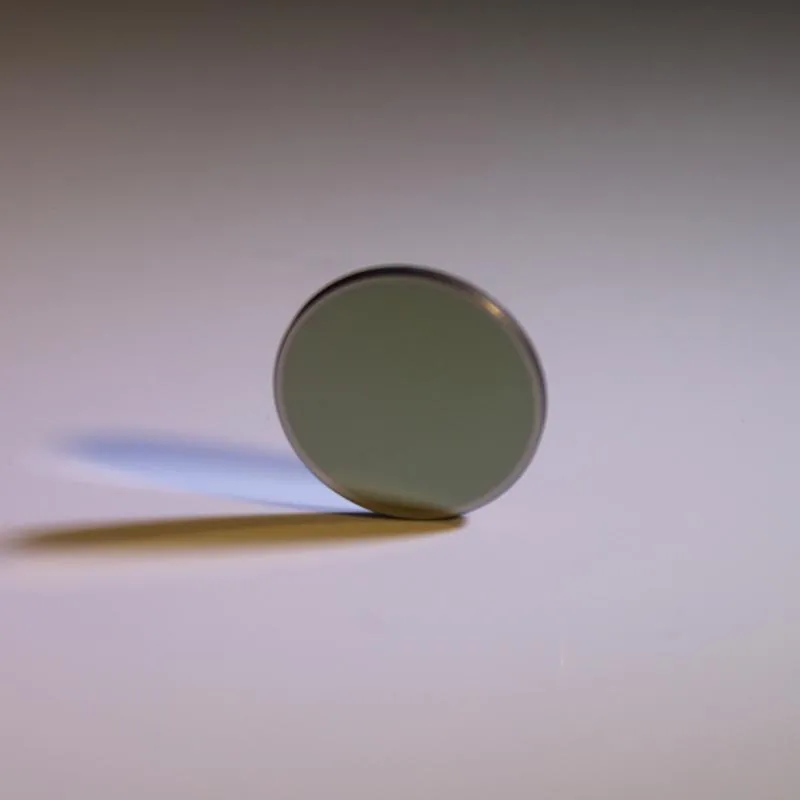

Ge Lenses: Optimal for Infrared and Thermal Imaging

Germanium (Ge) lenses are renowned for their superior optical characteristics in the infrared spectrum. With a high refractive index and excellent thermal stability, Ge lenses are extensively used in thermal imaging, night vision, and IR laser applications. These lenses offer exceptional performance in CO2 laser systems, ensuring precise laser beam focusing.

Key benefits of Ge lenses:

- Outstanding IR transmission between 2-14 µm

- High refractive index enabling compact optical designs

- Resistant to thermal shock and environmental factors

- Used in military, industrial, and medical applications

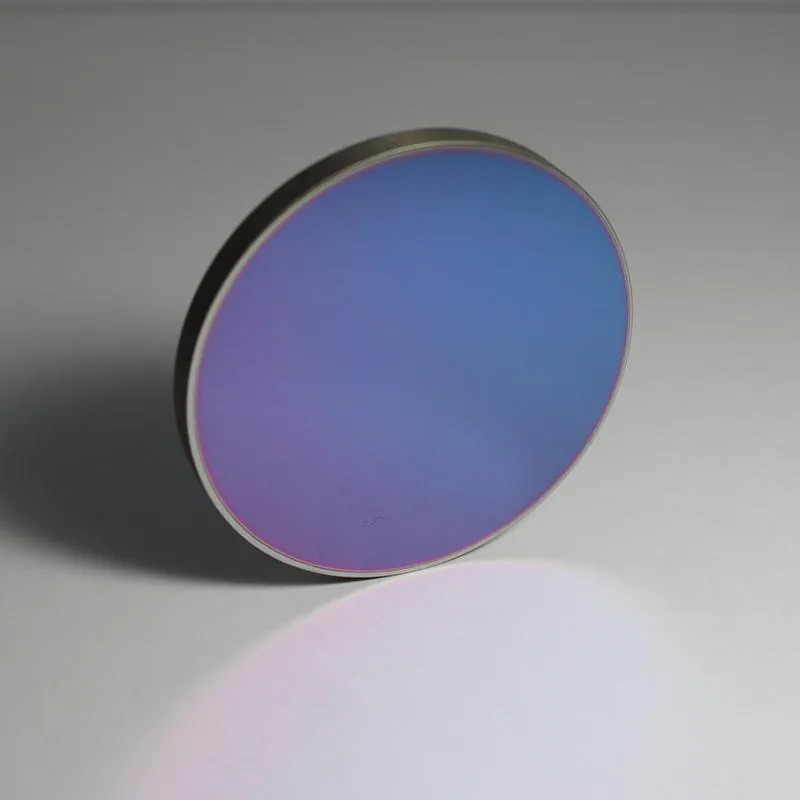

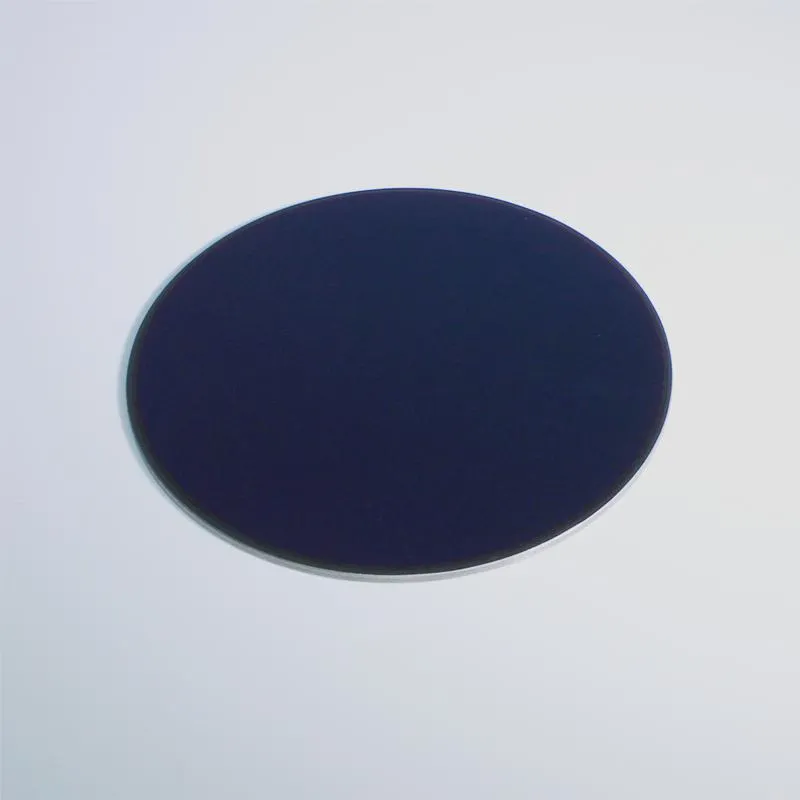

Si Lenses: High-Durability Optical Components

Silicon (Si) lenses are widely employed in laser optics due to their durability and excellent thermal conductivity. Si lenses are frequently used in mid-IR applications, including spectroscopy, thermal imaging, and laser cutting technologies. Their low density makes them an ideal choice for lightweight optical systems.

Features of Si lenses:

- Excellent IR transmission in the 1.2-8 µm range

- High thermal conductivity preventing overheating

- Lightweight yet robust design

- Cost-effective solution for various optical applications

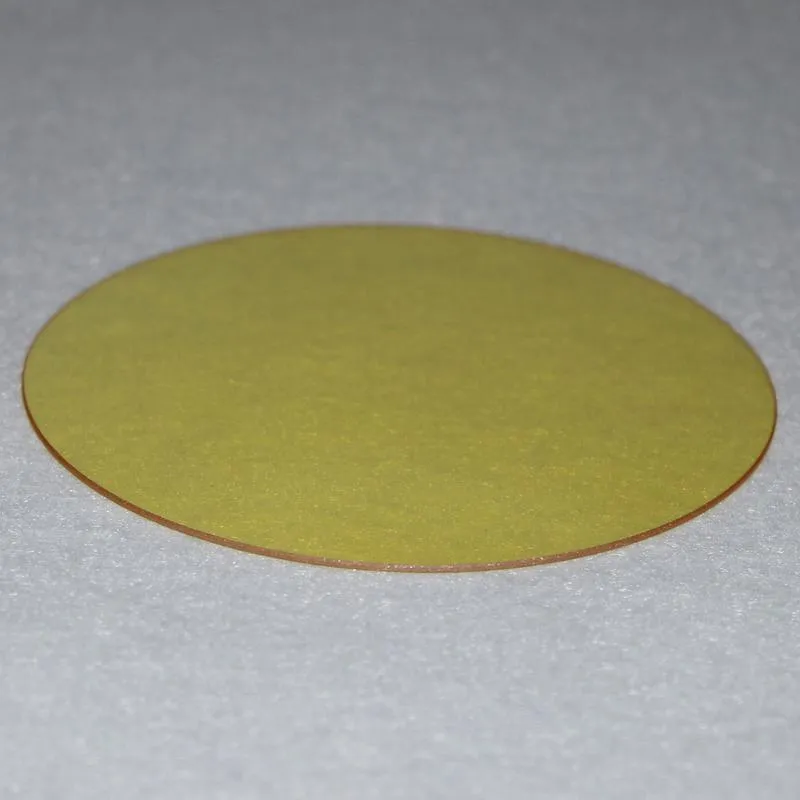

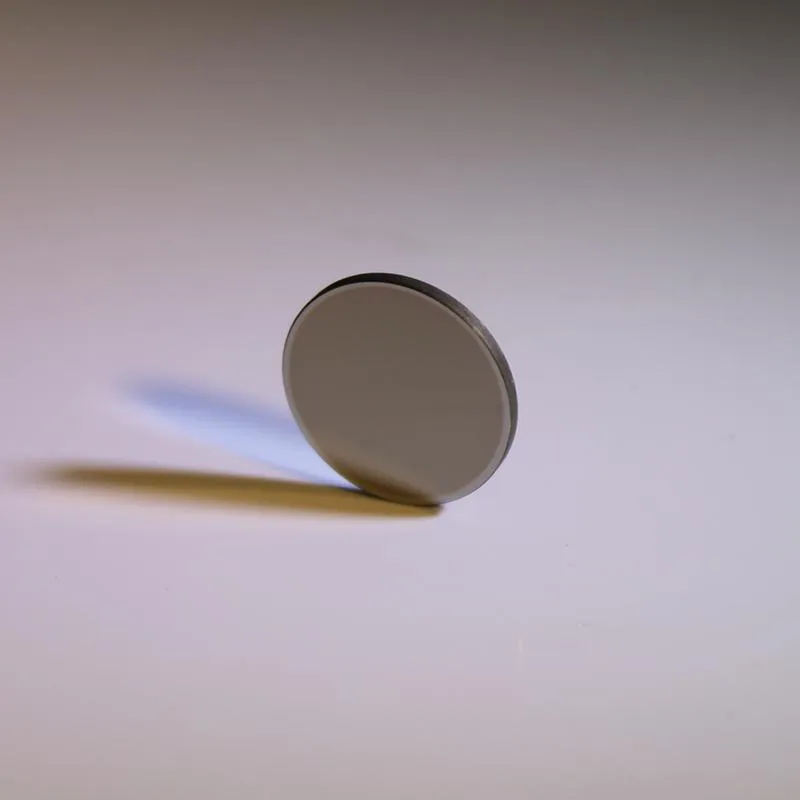

Barium Fluoride Lenses: High-Performance IR Optics

Barium Fluoride (BaF₂) lenses are highly valued for their broad spectral transmission and resistance to radiation damage. These lenses are widely used in high-power laser systems, medical imaging, and spectroscopic applications. The ability of barium fluoride lenses to transmit deep ultraviolet (UV) and mid-infrared (IR) light makes them an essential component in cutting-edge optical technologies.

Advantages of BaF₂ lenses:

- Wide spectral range: UV to mid-IR (0.15-12 µm)

- Excellent resistance to high radiation exposure

- Low refractive index variation with temperature

- Ideal for medical lasers, defense, and industrial applications

Why Choose High-Quality Optical Materials for Laser Machines?

Selecting the right optical components ensures superior laser performance, longevity, and efficiency. Materials like ZnSe, Ge, Si, and BaF₂ contribute to:

- Enhanced beam transmission: Minimizing energy loss for maximum efficiency

- High thermal stability: Ensuring long-lasting performance under extreme conditions

- Precision in laser applications: Achieving accurate and reliable results

- Versatility across industries: Used in medical, military, industrial, and research fields

When choosing optical components for laser machines, investing in high-quality materials like ZnSe, Ge, Si, and BaF₂ guarantees efficiency, durability, and precision. Whether for laser cutting, medical applications, or thermal imaging, these materials provide the best performance for demanding optical systems. Their exceptional optical properties make them indispensable in advancing laser technology across various industries.

We offer fast and secure shipping of ZnSe, Ge, Si, and BaF₂ optical materials across the USA and Europe, ensuring timely delivery for industrial, medical, and scientific applications. Our trusted logistics network guarantees safe handling and efficient transit, so you receive high-quality laser components without delays. Experience hassle-free international shipping with our reliable service.

Our Ordering Process

Send us your request with detailed specifications

Receive a commercial offer with terms and costs

After your approval, we handle manufacturing, quality control, and shipping

📦 Shipping

3-5 days in EU, from 10 days to USA

💳 Payment methods

Cash, Bank Transfer, Cards (Visa, Mastercard, Amex, Discover) and PayPal

💬 Questions?

Contact us via WhatsApp, phone, live chat or email