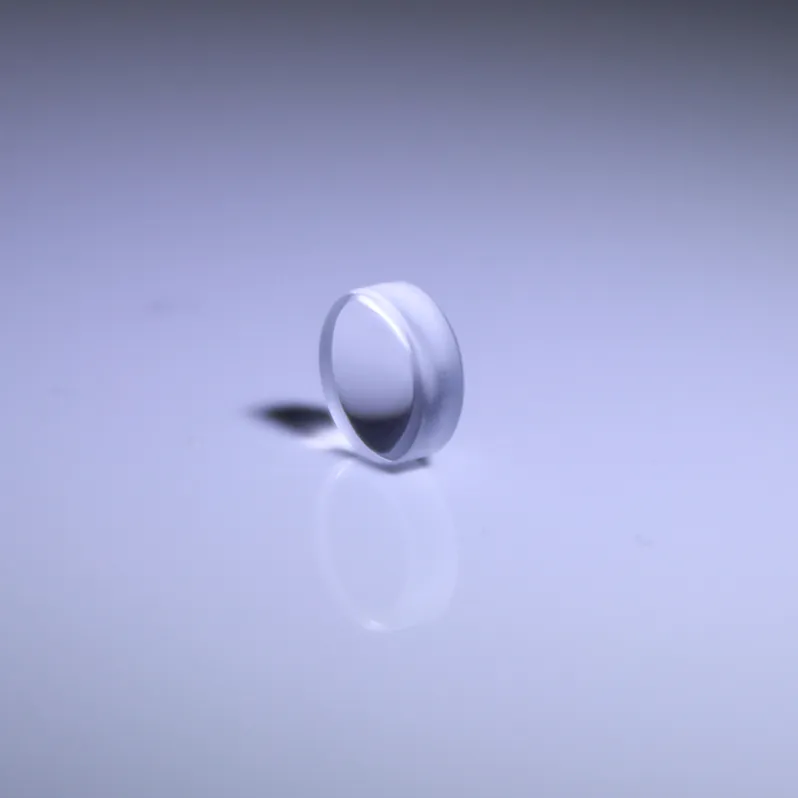

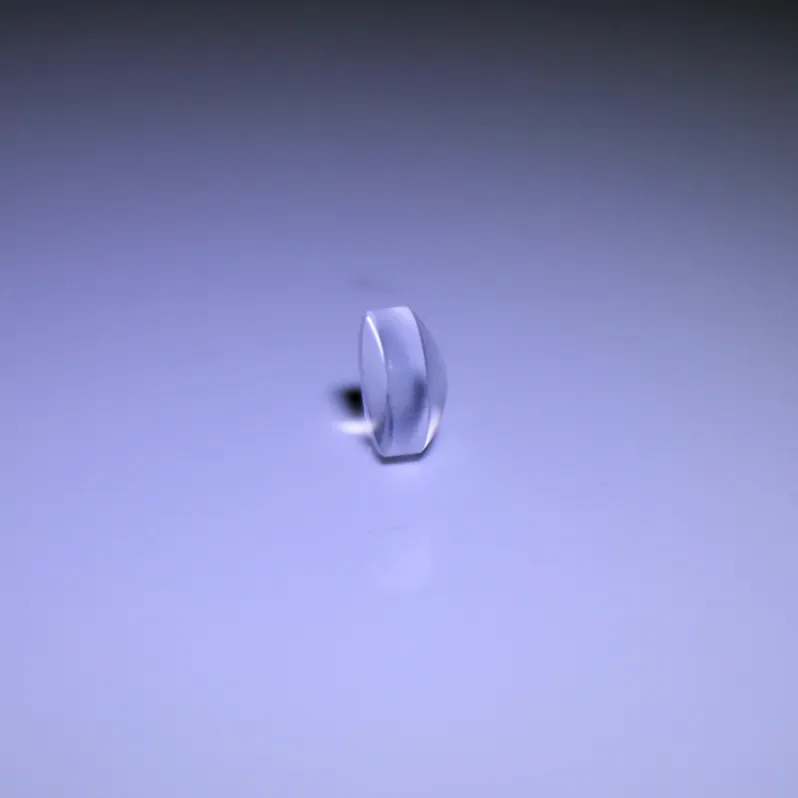

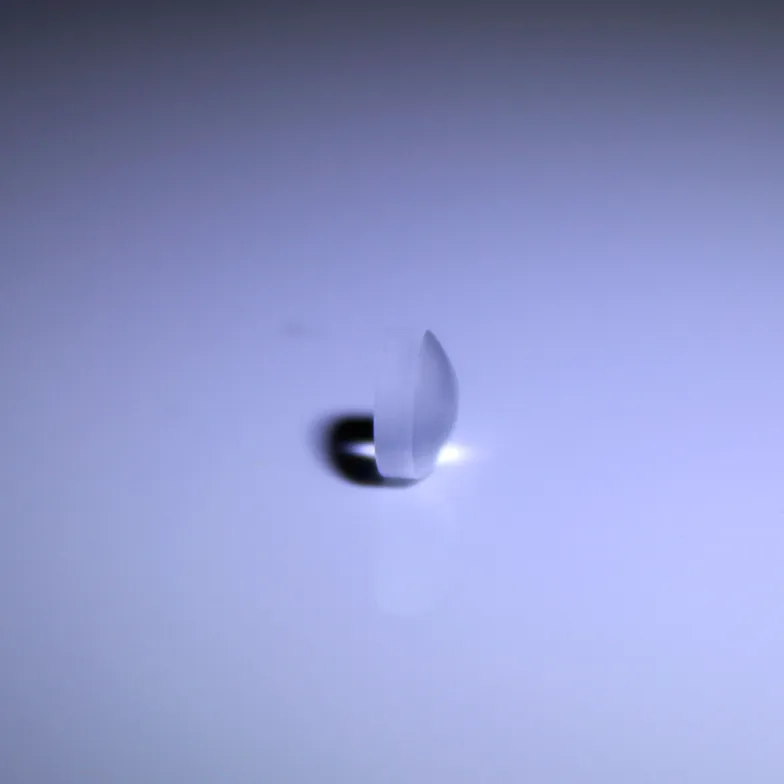

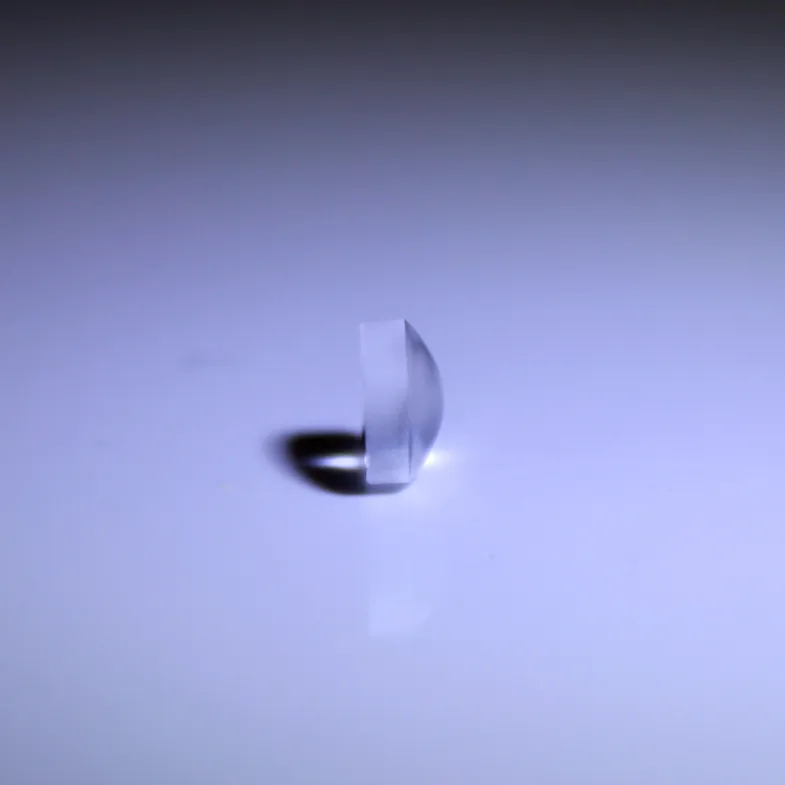

Aspherical Collimating Lens for Laser D 6mm Focal Length 4.60mm

Dimension: 6.00mm

Tolerance: +/-0.01mm

Surface Accuracy: 1lambda

Surface Quality: 60/40

Clear Aperature: 90%

Coating: Optional

1. What is an aspheric lens in glasses?

The combination of an aspheric design with high-index lens materials creates a lensthat is noticeably slimmer, thinner and lighter than conventional glass or plastic lenses. Whether you are nearsighted or farsighted, aspheric lenses are thinner and lighter and have a slimmer profile than ordinary lenses.

2. What does aspheric lens mean?

An aspheric lens or asphere (often labeled ASPH on eye pieces) is a lens whose surface profiles are not portions of a sphere or cylinder. … The asphere’s more complex surface profile can reduce or eliminate spherical aberration and also reduce other optical aberrations such as astigmatism, compared to a simple lens.

3. Are aspheric lenses more expensive?

Aspheric lenses are also more likely to have reflections, so it is important to get an anti-reflective coating on the lenses. This means that your lenses may cost more than traditional lenses made from plastic. … Right now, spherical lenses are still simpler to make, and they typically cost less.

4. What are the advantages of aspheric lenses?

Aspheric plus lenses reduce magnification for a more natural appearance, and 2. The decreased center thickness uses less material, resulting in less weight. Traditional lenses in high-plus powers cause the wearer to look directly in the lens center for good vision.

5. What is the difference between spherical and aspheric contact lenses?

By contrast, aspherical contact lenses don’t have a perfectly spherical shape. … In contrast, spherical contacts have a constant curvature and power across the lenssurface. The curvature of an aspheric contact lens deflects light rays in a way that corrects spherical aberration.

|

No |

Model |

D (mm) |

CA(mm) |

NA |

EFL(mm) |

CT(mm) |

ET(mm) |

Material |

DW(nm) |

AR Coating(nm) |

| 1 | VY_LTF0302 | Φ3.0 | 2.15/1.55 | 0.54 | 2 | 1.87 | 1.2 | D-ZK3 | 650 | 400-700/600-1050 |

| 2 | VY_HBF3038 | Φ3.0 | 2.4/2.3 | 0.3 | 3.77 | 1.5 | 1.2 | L-BAL35 | 635 | 400-700/700-1100 |

| 3 | VY_LTF0306 | Φ3.0 | 2.4/2.1 | 0.2 | 6 | 1.5 | 1.2 | D-ZK3 | 530 | 400-700/700-1100 |

| 4 | VY_LTF4762 | Φ4.7 | 3.7/2.55 | 0.3 | 6.2 | 3.484 | 2.864 | D-ZK3 | 633 | 400-700 |

| 5 | VY_LT4780 | Φ4.7 | 4.0/3.29 | 0.25 | 8 | 2.9 | 2.35 | D-ZK3 | 530 | 400-700 |

| 6 | VY_LTF0510 | Φ5.0 | 4.0/3.64 | 0.2 | 10 | 2 | 1.525 | D-ZK3 | 635 | 400-700/650-800 |

| 7 | VY_XMF6040 | Φ6.0 | 5.2/4.2 | 0.55 | 4 | 2.8 | 1.53 | D-LAK6 | 632.8 | 400-700 |

| 8 | VY_XMF6045 | Φ6.0 | 5.2/4.2 | 0.55 | 4.5 | 2.8 | 1.56 | D-LAK6 | 632.8 | 400-700 |

| 9 | VY_LTF0610 | Φ6.0 | 5.0/4.58 | 0.25 | 10 | 2 | 1.38 | D-ZK3 | 635 | 400-700/650-800 |

| 10 | VY_LTF0612 | Φ6.0 | 5.5/4.93 | 0.23 | 12 | 2.5 | 1.85 | D-ZK3 | 530 | 400-700/700-1100 |

| 11 | VY_LTF0615 | Φ6.0 | 5.0/4.5 | 0.15 | 15 | 2.1 | 1.69 | D-ZK3 | 635 | 400-700/700-1100 |

| 12 | VY_LTF6340 | Φ6.33 | 5.0/4.6 | 0.6 | 4.05 | 3.3 | 1.49 | D-ZK3 | 445 | 400-700/700-1100 |

| 13 | VY_LTF6380 | Φ6.325 | 5.3/4.87 | 0.33 | 8 | 1.91 | 1 | D-ZK3 | 530 | 400-700/700-1100 |

| 14 | VY_HBF63510 | Φ6.35 | 3.5/3 | 0.17 | 10 | 3 | 1.8 | L-BAL42 | 786.5 | 786.5±20 |

| 15 | VY_XMF0708 | Φ7.0 | 6.5/6.0 | 0.4 | 8 | 2.3 | 0.89 | D-ZK2 | 635 | 400-700 |

| 16 | VY_HBF0811 | Φ8.0 | 7.0/6.5 | 0.31 | 11.2 | 2.66 | 1.7 | D-ZK3 | 635 | 400-700/700-1100 |

| 17 | VY_LTF0815 | Φ8.5 | 8.0/7.48 | 0.27 | 15 | 2.5 | 1.52 | D-ZK3 | 635 | 400-700/700-1100 |

| 18 | VY_HBF1015 | Φ10.5 | 9.2/8.4 | 0.3 | 15.18 | 3 | 1.28 | L-BAL42 | 639 | 400-700/700-1100 |

Our Ordering Process

Send us your request with detailed specifications

Receive a commercial offer with terms and costs

After your approval, we handle manufacturing, quality control, and shipping

📦 Shipping

3-5 days in EU, from 10 days to USA

💳 Payment methods

Cash, Bank Transfer, Cards (Visa, Mastercard, Amex, Discover) and PayPal

💬 Questions?

Contact us via WhatsApp, phone, live chat or email