Bio Sensor

Cut Type: Thickness Shear Mode (TSM)

Nominal Frequency: 16.5 MHz +/- 165KHz

Crystal Cutting: 35 degrees 15' +/- 3' (AT cut)

Operating Temperature: 37º C +/- 2º C

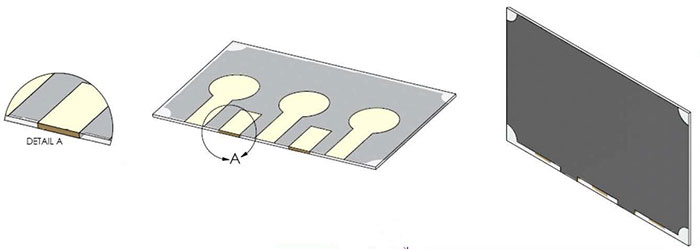

Footprint Size: 8.6 +/- 0.05 mm x 5.4 +/- 0.05 mm, see drawing1

A biosensor is an analytical device, used for the detection of an analyte , that combines a biological component with a physicochemical detector. The sensitive biological element is a biologically derived material or biomimetic component that interacts (binds or recognizes) with the analyte under study.

The biologically sensitive elements can also be created by biological engineering. The transducer or the detector element (works in a physicochemical way; optical, piezoelectric, electrochemical, etc.) transforms the signal resulting from the interaction of the analyte with the biological element into another signal (i.e., transduces) that can be more easily measured and quantified. The biosensor reader device with the associated electronics or signal processors that are primarily responsible for the display of the results in a user-friendly way. We are usually custom-designed and manufactured to suit the different working principles of biosensors.

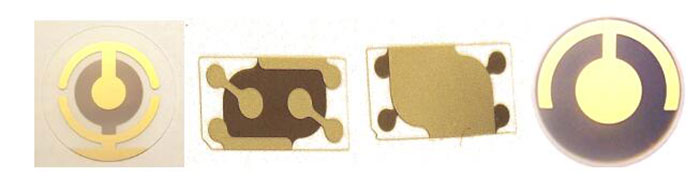

Our running series typical chips

The following spec sheet is a typical one, you may freely tell us and we’ll pleased to customize them for you.

| Quantity | More than 1.5 million monthly |

| Cut Type | Thickness Shear Mode (TSM) |

| Nominal Frequency | 16.5 MHz +/- 165KHz |

| Crystal Cutting | 35 degrees 15′ +/- 3′ (AT cut) |

| Operating Temperature | 37º C +/- 2º C |

| Footprint Size | 8.6 +/- 0.05 mm x 5.4 +/- 0.05 mm, see drawing1 |

| Bottom Side | 3 1.7 mm diameter |

| Number of Electrodes | |

| Electrode Size | |

| Top Side | 18.6 mm x 5.4 mm |

| Number of Electrodes | |

| Electrode Size | |

| Electrode Plating | 10nm Chromium Layer90nm Gold Layer |

| Shear force | ≥7g |

| Deposition Rate | 0.8 nms-1 at nominal room temperature |

| Aging frequency drift at 25 degrees: | ≤2% |

| Temperature frequency shift (how much can the frequency change

over the operating temperature range of 35 to 39 degrees) |

as low as possible (e.g. << 1 ppm) |

| Storage temperature range | assume similar range for IVD device (e.g. 2 °C to 30 °C) |

| Shunt capacitance and load capacitance spec | no preference |

| Voltage which it will be driven | in the 100s mV range |

| Drive level amount of power that will be dissipated | no preference |

| Insulation resistance | expect less than 200 ohms, see drawing 2 |

| ESR (equivalent series resistance) | low ESR and high quality factor |

Our Ordering Process

Send us your request with detailed specifications

Receive a commercial offer with terms and costs

After your approval, we handle manufacturing, quality control, and shipping

📦 Shipping

3-5 days in EU, from 10 days to USA

💳 Payment methods

Cash, Bank Transfer, Cards (Visa, Mastercard, Amex, Discover) and PayPal

💬 Questions?

Contact us via WhatsApp, phone, live chat or email