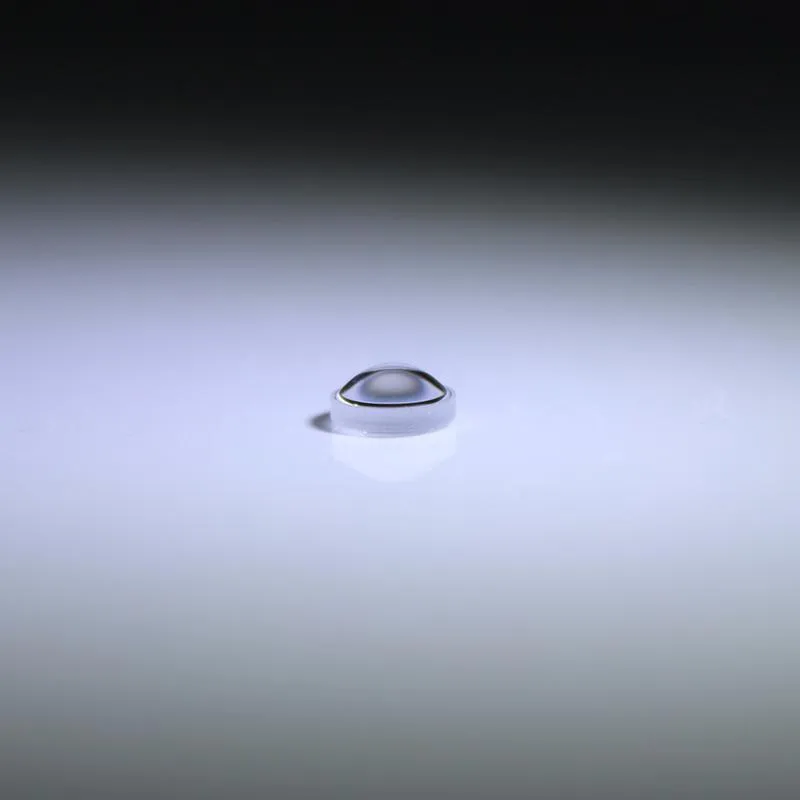

Blue Laser Collimating Aspheric Lenses

Dimension: +/-0.01 mm

Surface Accuracy: 60/40

Size Tolerance: 5/1

Angle Tolerance: 95%

Coating: 0.05mm, standard; 0.01,attainable.

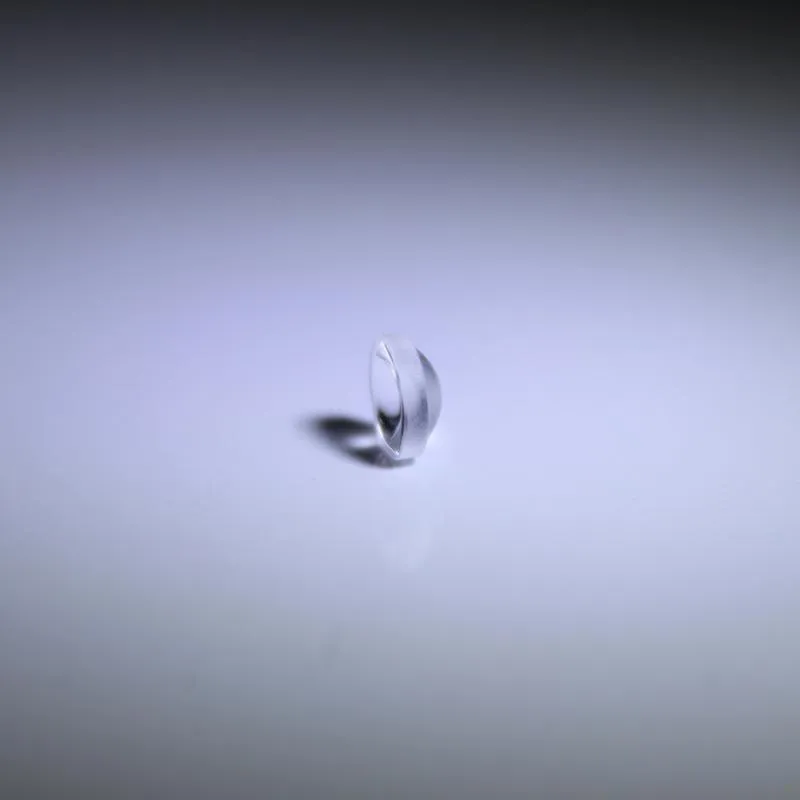

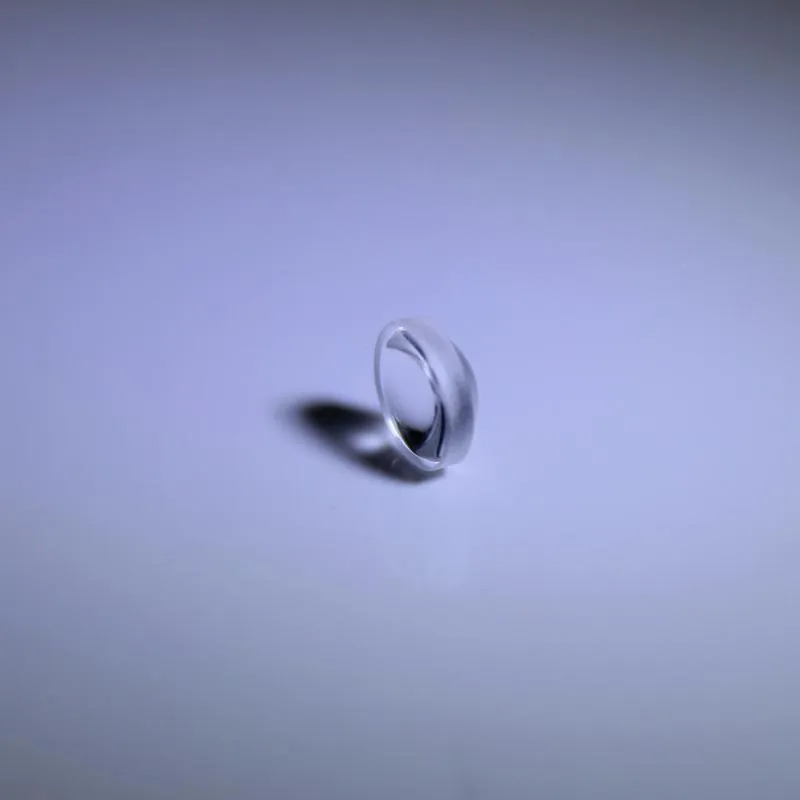

Aspheric lenses allow optical designers to correct aberrations using fewer elements than conventional spherical optics because the former gives them more aberration correction than multiple surfaces of the latter. For example, in zoom lenses where ten or more lens elements are typically used, two aspheric lenses can be substituted for a handful of spherical lenses in order to achieve similar or better optical results, while reducing system size and potentially reducing the overall cost of production.

The most notable benefit of aspheric lenses is their ability to correct for spherical aberration, an optical effect which causes incident light rays to focus at different points when forming an image, creating a blur. Spherical aberration is commonly seen in spherical lenses, such as plano-convex or double-convex lens shapes, but aspheric lenses focus light to a small point, creating comparatively no blur and improving image quality. Spherical aberration is inherent in the basic shape of a spherical surface and is independent of alignment or manufacturing errors; in other words, a perfectly designed and manufactured spherical lens will still inherently exhibit spherical aberration. An aspheric lens can be designed to minimize aberration by adjusting the conic constant and aspheric coefficients of the curved surface of the lens.

● Blue Laser Collimating Aspheric Lenses

1) Designs Optimized for 405nm and 488nm Laser Diodes

2) Ideal for Biomedical Instrumentation and Data Storage Applications

3) Diffraction Limited Molded Aspheric Lens Designs

● Common Specifications

1) Coating: BBAR (350-500nm)

2) Surface Quality: 40-20

3) Center Thickness Tolerance (mm): ±0.05

4) Coating Specification: Rabs <1.0% @ 350 – 500nm

5) Wavelength Range (nm): 350 – 500

|

No |

Model |

D (mm) |

CA(mm) |

NA |

EFL(mm) |

CT(mm) |

ET(mm) |

Material |

DW(nm) |

AR Coating(nm) |

| 1 | VY_LTF0302 | Φ3.0 | 2.15/1.55 | 0.54 | 2 | 1.87 | 1.2 | D-ZK3 | 650 | 400-700/600-1050 |

| 2 | VY_HBF3038 | Φ3.0 | 2.4/2.3 | 0.3 | 3.77 | 1.5 | 1.2 | L-BAL35 | 635 | 400-700/700-1100 |

| 3 | VY_LTF0306 | Φ3.0 | 2.4/2.1 | 0.2 | 6 | 1.5 | 1.2 | D-ZK3 | 530 | 400-700/700-1100 |

| 4 | VY_LTF4762 | Φ4.7 | 3.7/2.55 | 0.3 | 6.2 | 3.484 | 2.864 | D-ZK3 | 633 | 400-700 |

| 5 | VY_LT4780 | Φ4.7 | 4.0/3.29 | 0.25 | 8 | 2.9 | 2.35 | D-ZK3 | 530 | 400-700 |

| 6 | VY_LTF0510 | Φ5.0 | 4.0/3.64 | 0.2 | 10 | 2 | 1.525 | D-ZK3 | 635 | 400-700/650-800 |

| 7 | VY_XMF6040 | Φ6.0 | 5.2/4.2 | 0.55 | 4 | 2.8 | 1.53 | D-LAK6 | 632.8 | 400-700 |

| 8 | VY_XMF6045 | Φ6.0 | 5.2/4.2 | 0.55 | 4.5 | 2.8 | 1.56 | D-LAK6 | 632.8 | 400-700 |

| 9 | VY_LTF0610 | Φ6.0 | 5.0/4.58 | 0.25 | 10 | 2 | 1.38 | D-ZK3 | 635 | 400-700/650-800 |

| 10 | VY_LTF0612 | Φ6.0 | 5.5/4.93 | 0.23 | 12 | 2.5 | 1.85 | D-ZK3 | 530 | 400-700/700-1100 |

| 11 | VY_LTF0615 | Φ6.0 | 5.0/4.5 | 0.15 | 15 | 2.1 | 1.69 | D-ZK3 | 635 | 400-700/700-1100 |

| 12 | VY_LTF6340 | Φ6.33 | 5.0/4.6 | 0.6 | 4.05 | 3.3 | 1.49 | D-ZK3 | 445 | 400-700/700-1100 |

| 13 | VY_LTF6380 | Φ6.325 | 5.3/4.87 | 0.33 | 8 | 1.91 | 1 | D-ZK3 | 530 | 400-700/700-1100 |

| 14 | VY_HBF63510 | Φ6.35 | 3.5/3 | 0.17 | 10 | 3 | 1.8 | L-BAL42 | 786.5 | 786.5±20 |

| 15 | VY_XMF0708 | Φ7.0 | 6.5/6.0 | 0.4 | 8 | 2.3 | 0.89 | D-ZK2 | 635 | 400-700 |

| 16 | VY_HBF0811 | Φ8.0 | 7.0/6.5 | 0.31 | 11.2 | 2.66 | 1.7 | D-ZK3 | 635 | 400-700/700-1100 |

| 17 | VY_LTF0815 | Φ8.5 | 8.0/7.48 | 0.27 | 15 | 2.5 | 1.52 | D-ZK3 | 635 | 400-700/700-1100 |

| 18 | VY_HBF1015 | Φ10.5 | 9.2/8.4 | 0.3 | 15.18 | 3 | 1.28 | L-BAL42 | 639 | 400-700/700-1100 |

Our Ordering Process

Send us your request with detailed specifications

Receive a commercial offer with terms and costs

After your approval, we handle manufacturing, quality control, and shipping

📦 Shipping

3-5 days in EU, from 10 days to USA

💳 Payment methods

Cash, Bank Transfer, Cards (Visa, Mastercard, Amex, Discover) and PayPal

💬 Questions?

Contact us via WhatsApp, phone, live chat or email