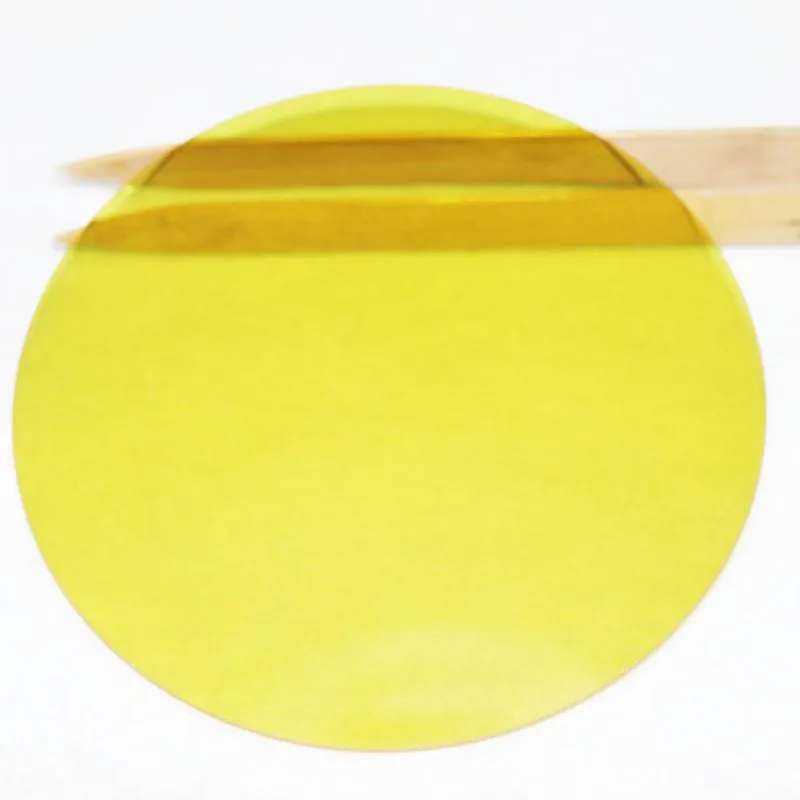

Diameter 25mm Zinc Selenide (ZnSe) Lens

Melting Point: 1525°C (dissociates about 700°C)

Thermal Conductivity: 18 W/(m K) at 298K

Thermal Expansion: 7.1 x 10-6/°C at 273K

Hardness Knoop: 120 with 50g indenter

Size: 3mm-200mm

Thickness: 0.50mm-30mm

Tolerance: +/-0.05mm

What is Zinc Selenide (ZnSe) Component?

Zinc Selenide (ZnSe) optical components are specifically designed for infrared (IR) spectroscopy. ZnSe lenses and windows can be used in applications such as thermal imaging or FLIR (Forward-Looking Infrared). ZnSe optical components are ideal for integration into CO2 laser systems due to their low absorption coefficient and high resistance to thermal shock. However, ZnSe material is not recommended for use in harsh environments.

Product Showcase

The image above shows a 25mm ZnSe window used in temperature measurement systems. We supply a wide range of ZnSe components, including:

- Optical ZnSe lenses

- Optical ZnSe windows

- ZnSe prisms

- ZnSe plate beamsplitters

- ZnSe focusing objectives

We welcome custom designs and drawings to meet your specific requirements. Contact us to customize your ZnSe components!

Ideal for Thermal Imaging

Zinc Selenide has low infrared absorption and can transmit light across a very wide spectral range (0.6–16 µm). This makes it highly conducive to thermal imaging, which relies on analyzing the black body radiation spectrum of distant objects. Long-wave transmission is particularly important for imaging objects at room temperature. The maximum radiation wavelength of objects at room temperature is approximately 10 µm, with relatively low radiation intensity.

Heat Resistance

Zinc Selenide windows are suitable for environments requiring great heat resistance due to their low absorption and high thermal shock resistance. This is why ZnSe windows are commonly used in high-power CO2 laser applications. Additionally, these windows are also used in infrared imaging applications such as scientific research, military operations, and search-and-rescue missions.

Softness of Zinc Selenide Material

Due to the softness of the material, you should handle ZnSe components only by their edges to avoid warping. Pressure should be applied uniformly during handling. When cleaning ZnSe optical devices, take care to avoid scratching the soft surface:

- Dust or lint particles can usually be blown off using a dust-free blower or air bulb.

- If further cleaning is required, use acetone or isopropanol to clean the surface.

- While holding the edge of the optical element, gently wipe the surface with a damp cotton ball. Avoid rubbing or applying pressure.

- Only use surgical-quality cotton balls for cleaning.

Note: Zinc Selenide is toxic, so protective rubber gloves should always be worn when handling ZnSe components.

Our Ordering Process

Send us your request with detailed specifications

Receive a commercial offer with terms and costs

After your approval, we handle manufacturing, quality control, and shipping

📦 Shipping

3-5 days in EU, from 10 days to USA

💳 Payment methods

Cash, Bank Transfer, Cards (Visa, Mastercard, Amex, Discover) and PayPal

💬 Questions?

Contact us via WhatsApp, phone, live chat or email