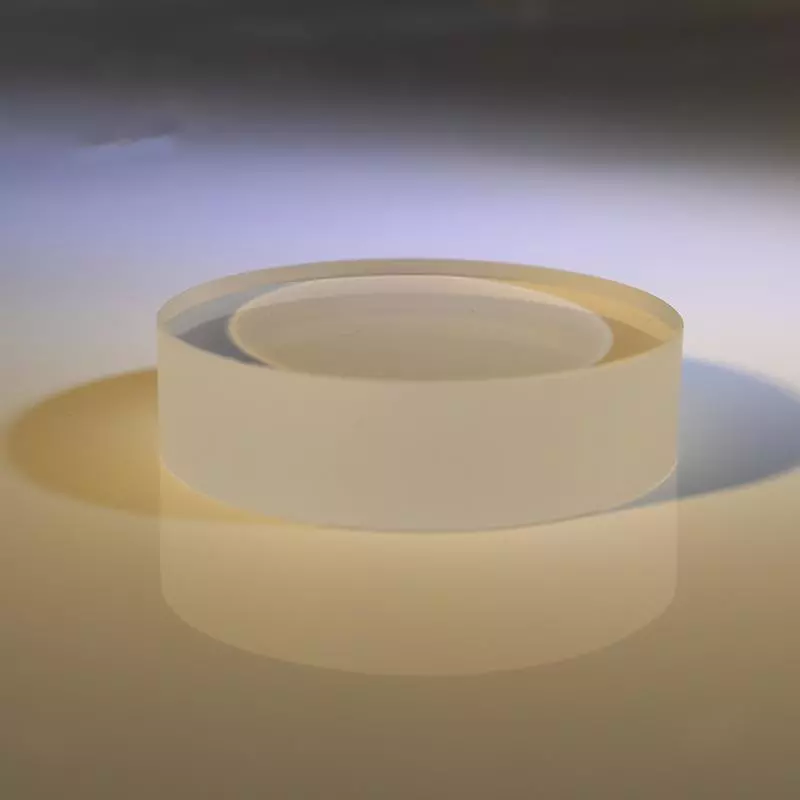

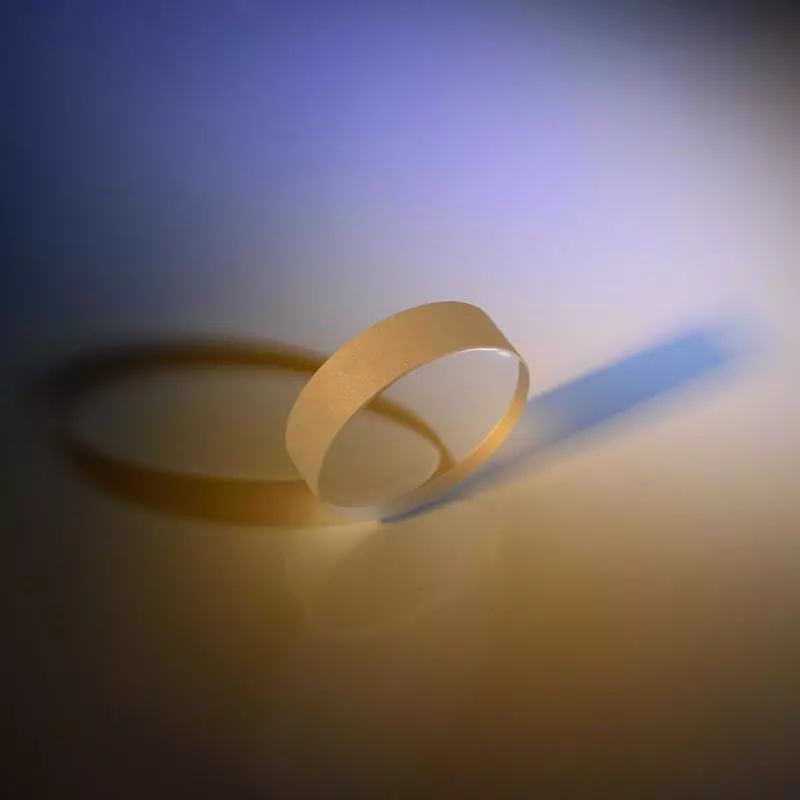

Fused Silica Windows & Fused Quartz Windows

Dimension: 1.0mm-460mm

Thickness: 0.1mm-30mm

Surface Accuracy: lambda/20

Surface Quality: 10-5

Tolerance: +/-0.01mm

Parallelism: 30"

Fused Quartz, Fused Silica Windows and Plates

We have the capabilities to produce fused quartz windows from 1.00mm diameter to 400.00mm diameter and thicknesses from 0.20mm up to 120.00mm.

Our standard specifications for fused quartz windows dimensional tolerances are +/-0.0mm with a scratch/dig polished surface specification of 60/40 mil spec or better. Standard flatness is 2-4 wavelengths per inch.

All fused quartz windows can be rated for pressure as long as the unsupported working diameter is supplied.

We process a range of optical windows in a selection of materials to meet all scientific instrument applications from UV-Visible and NIR wavelengths. We stock different grades dependent on application, from high quality precision N-BK7 or equivalent type with flat and parallel faces for imaging applications to simple white float windows for general purpose instrument applications.

Customized Specification of quartz glass window

| Dimensions | Diameters 1.0mmmm to 400mm

Commercial grade up to 1200mm x 1200mm |

| Thickness Range | 0.1mm to 50mm (subject to dimension) |

| Dimension/Thickness | Tol up to 0.01mm |

| Edge Finish | Ground or polished |

| Surface Quality | 80/50 to 20/10 scratch/dig |

| Surface Flatness | Up to lambda 10 (@633nm) |

| Parallelism | Up to 10 seconds |

| Material Options | Commercial Grade Quartz, Heraeus Herasil, GE124 |

| Coating Options | AR coatings |

| Options | Edges polished, wedges, shapes, drilled holes & bevelled angles |

Quartz glass has a series of excellent physical and chemical properties

1. High temperature resistance: The softening point temperature of quartz glass is 1730 degrees Celsius, it can be used for a long time at 1100 degrees Celsius, and the maximum use temperature can reach 1450 degrees Celsius in a short time;

2. Corrosion resistance: Except for hydrofluoric acid, quartz glass hardly reacts with other acids. Its acid resistance is 30 times that of ceramics and 150 times that of stainless steel, especially its chemical stability at high temperatures. It is unmatched by any other engineering materials.

3. Good thermal stability: The thermal expansion coefficient of quartz glass is extremely small, and it can withstand severe temperature changes. When the quartz glass is heated to about 1100 degrees Celsius, it will not burst when placed in water at room temperature.

4. Good light transmittance: Quartz glass has good light transmittance in the entire spectral band from ultraviolet to infrared waveband, the transmittance of quartz glass in the visible light is above 93%, especially in the ultraviolet spectral range, the maximum transmittance can reach above 80% .

5. Good electrical insulation performance: The resistance value of quartz glass is equivalent to 10,000 times that of ordinary glass. It is an excellent electrical insulation material and has excellent electrical properties even at high temperatures.

Quartz glass is widely used in various fields such as electric light source, semiconductor, optical communication, military industry, metallurgy, building materials, chemistry, machinery, electric power and environmental protection because of its excellent properties.

Precautions for use

1. Quartz glass products are precious materials, so they need to be handled with care when using them;

2. All kinds of quartz glass have a higher operating temperature, and should not exceed this temperature during use, otherwise it will be softened and deformed;

3. Quartz glass that needs high temperature use must be wiped clean before use. It can be soaked in 10% hydrofluoric acid or lotion, and then cleaned with high-purity water or treated with alcohol. Wear gloves during operation and do not directly touch the quartz glass with your hands;

4. Quartz glass products are allowed to be used continuously under high temperature, which is good for prolonging the life of quartz glass and improving temperature resistance. On the contrary, if quartz optical glass products are used intermittently at high temperatures, the number of uses is limited;

5. Optical quartz glass material has extremely high thermal stability and can withstand drastic temperature changes. However, in actual use, it is different from the residual strain and product shape, and there is a certain difference in thermal stability. Pay attention to it when using it;

6. Quartz glass is an acidic material, strictly avoid contact with alkaline substances when used at high temperature, otherwise its anti-crystallization performance will be greatly reduced.

People Also Ask

What is quartz glass used for?

Quartz glass is used in the manufacturing of optical devices, lighting systems, refractory materials, and chemical apparatuses.

What is quartz window?

UQG Optics Fused Quartz is a useful material as it is stronger than general glass. It can withstand high temperatures up to 1050° and a high transmission from 260nm-2500nm. Used as a good protection window in cameras and high-pressure applications for an increased UV transmission.

What is silica glass used for?

Silica is used to produce flat glass we see in buildings across the world. However, the glass industry not only supplies construction materials but also enables the manufacturing of windshields and windows for the automobile industry.

Is glass harder than quartz?

Quartz crystals are harder than glass. Glass ranks around 5.5 on the Mohs scale. Quartz crystals rank as 7 on the Mohs scale. Therefore, a piece of quartz crystal will scratch a piece of glass.

How can you tell the difference between quartz and glass?

To tell glass from quartz, consider the characteristics of each. Glass may have round bubbles, quartz will not. Quartz will scratch glass due to differences in hardness. Use a gem tester to test thermal conductivity.M

Our Ordering Process

Send us your request with detailed specifications

Receive a commercial offer with terms and costs

After your approval, we handle manufacturing, quality control, and shipping

📦 Shipping

3-5 days in EU, from 10 days to USA

💳 Payment methods

Cash, Bank Transfer, Cards (Visa, Mastercard, Amex, Discover) and PayPal

💬 Questions?

Contact us via WhatsApp, phone, live chat or email