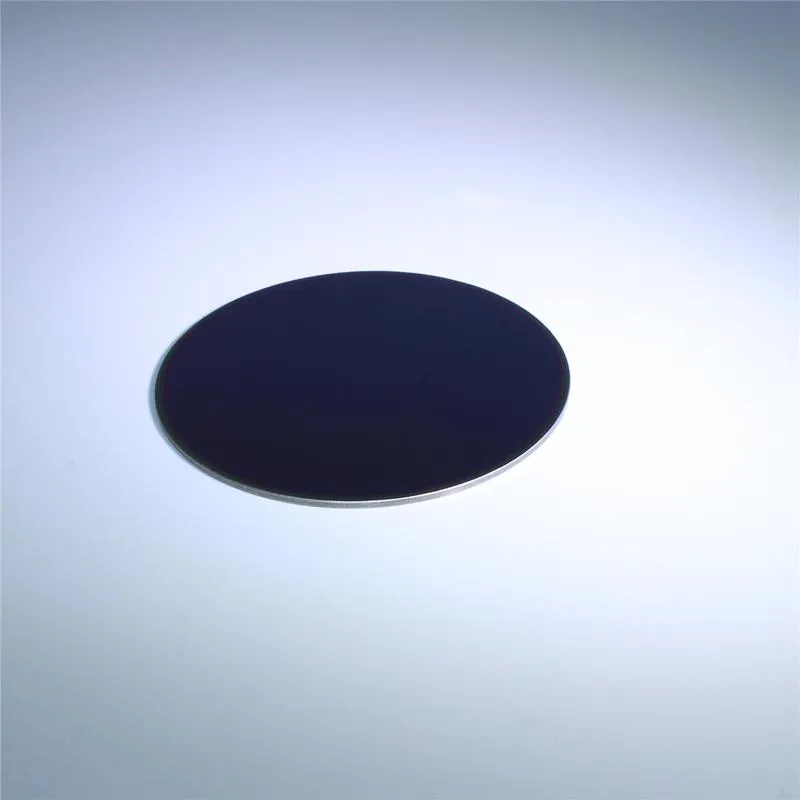

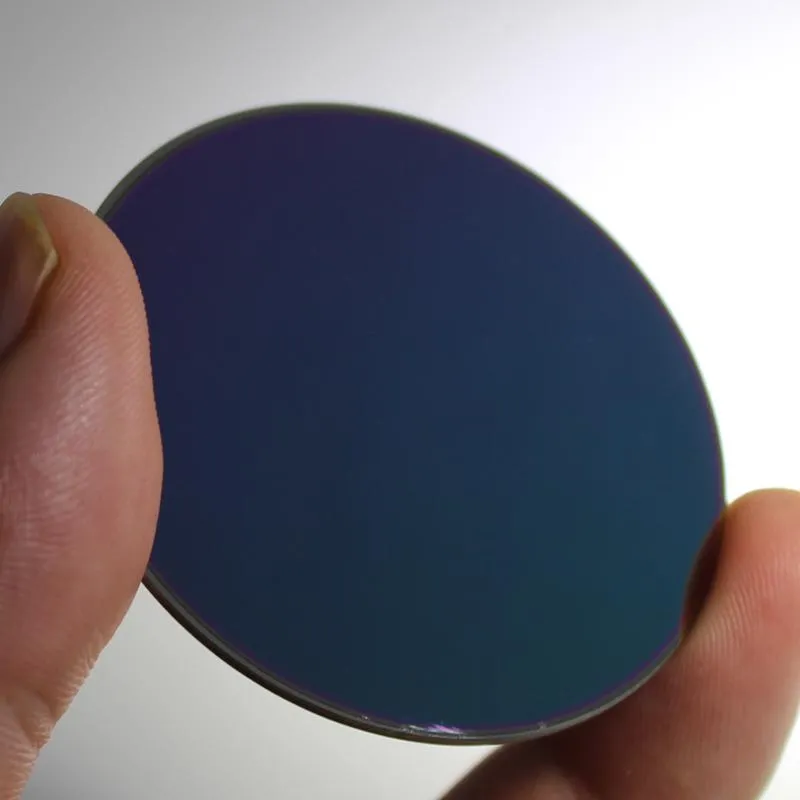

Germanium wafer with AR coating D55mm

Dimension: Dia. 60.00mm

Thickness: 10.00mm

Tolerance : +/-0.10mm

Germanium Wafer D55mm with AR Coating: A Versatile Optical Solution

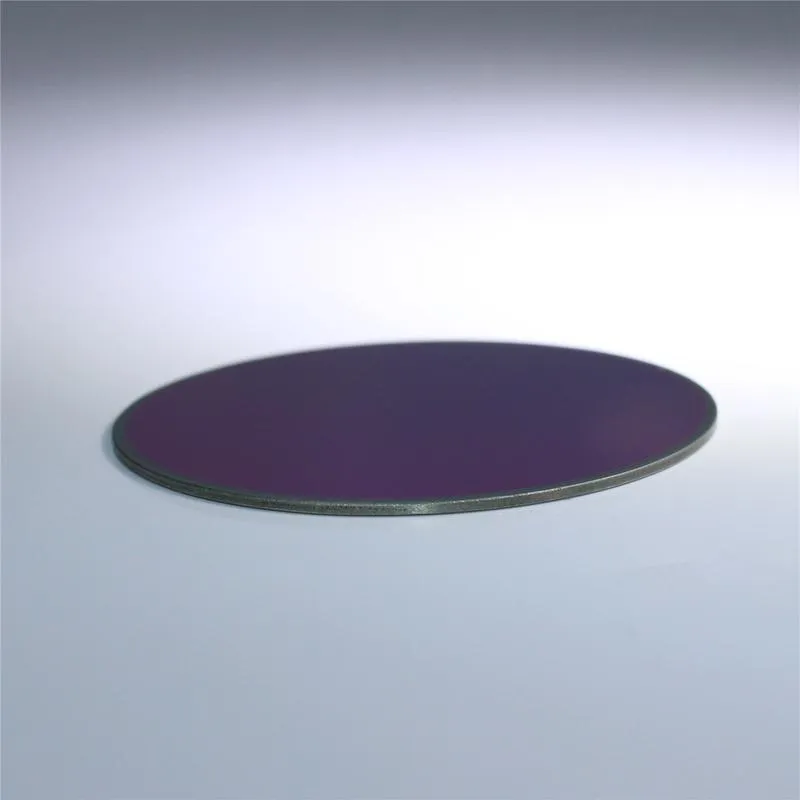

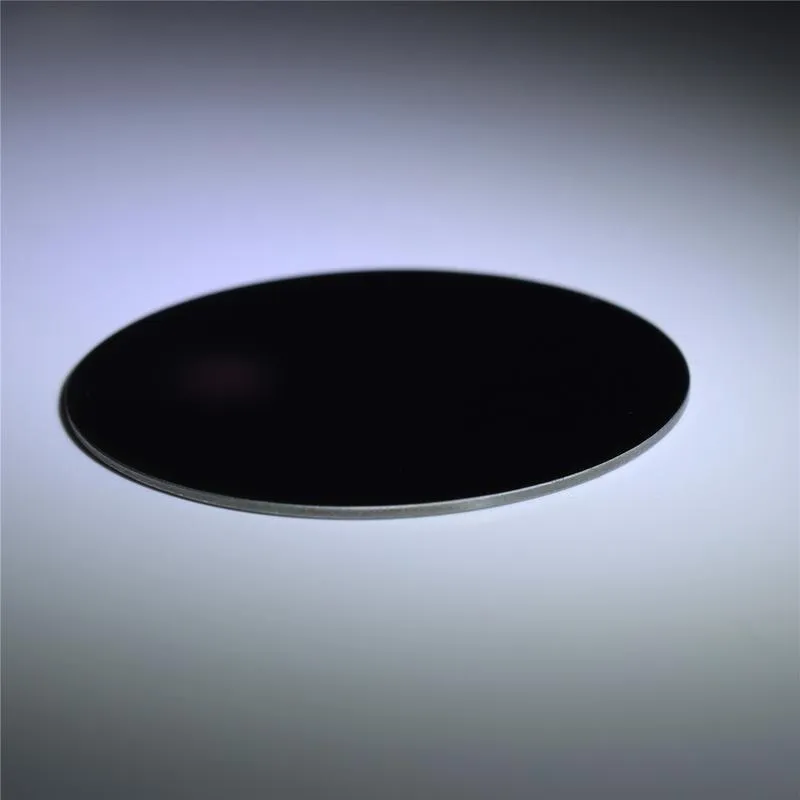

Germanium wafers, particularly those with anti-reflection (AR) coatings, are indispensable in advanced optical and infrared systems. The Ge wafer shown in the image has a diameter of 55mm, a thickness of 1mm, and features AR coatings on both surfaces optimized for the 7–14μm wavelength range, achieving an average transmission (Tavg) exceeding 95%. These characteristics make it ideal for high-performance applications such as thermal imaging, spectroscopy, and multispectral optics.

Technical Characteristics of Germanium Wafers

Germanium is renowned for its unique combination of physical and optical properties, which contribute to its widespread use in specialized applications:

– High Refractive Index: Germanium’s refractive index (~4.0) ensures excellent light absorption and minimal reflection losses. However, this property also necessitates AR coatings to enhance transmission efficiency.

– Thermal Runaway: One limitation of Germanium is its sensitivity to temperature changes. As temperatures rise, its transmission decreases—a phenomenon known as thermal runaway. This makes it unsuitable for environments above 100°C.

– High Density: With a density of 5.33 g/cm³, Germanium is relatively heavy compared to other materials. While this characteristic may pose challenges in weight-sensitive designs, it offers stability and durability in rugged conditions.

– Mechanical Hardness: Germanium boasts a Knoop Hardness of 780, nearly twice that of magnesium fluoride. This exceptional hardness ensures resistance to scratches and wear, making it suitable for demanding environments where robustness is critical.

Property of Germanium

- Clear Aperture (%): 90.00

- Dimensional Tolerance (mm): +0.0/-0.1

- Coefficient of Thermal Expansion CTE (10-6/°C): 6.1

- Density (g/cm3): 5.33

- Index of Refraction nd: 4.002 @ 11µm

- Knoop Hardness (kg/mm2): 780.00

- Parallelism (arcmin): <1

- Poisson’s Ratio: 0.28

- Substrate: Germanium (Ge)

- Surface Quality: 60-40

- Thickness Tolerance (mm): ±0.1

Advantages of Germanium Wafers with AR Coatings

The inclusion of AR coatings on Germanium wafers significantly enhances their performance across various applications. Below are some key advantages:

– Enhanced Transmission: AR coatings reduce surface reflections, ensuring maximum light transmission through the wafer. For example, the D55mm wafer achieves Tavg >95% in the 7–14μm range, making it highly efficient for infrared applications.

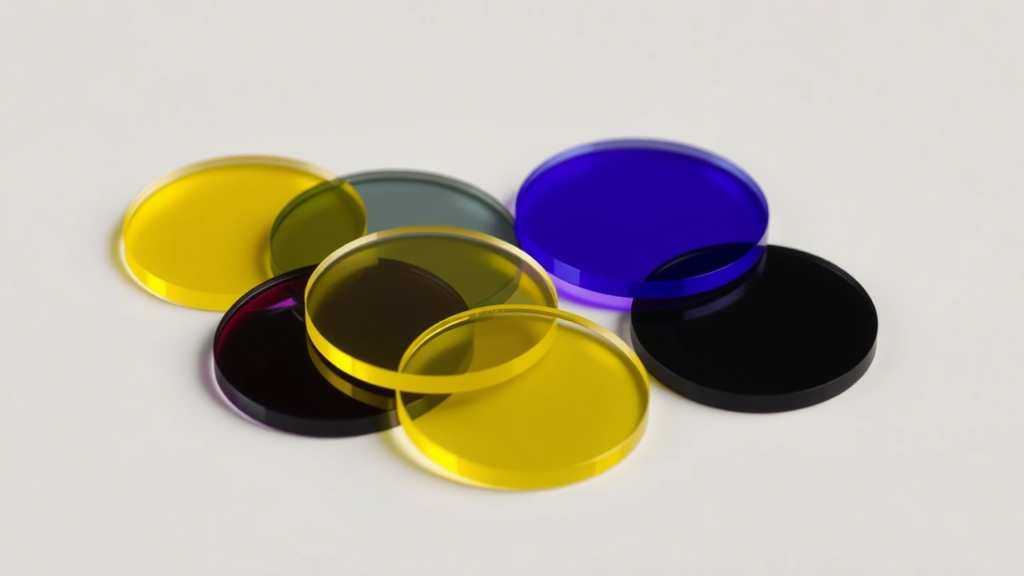

– Versatility Across Spectral Ranges: Germanium windows are available with three distinct AR coating options:

– 3–5μm: Ideal for mid-infrared applications such as gas sensing and spectroscopy.

– 3–12μm: Suitable for broadband multispectral tasks, including environmental monitoring and defense systems.

– 8–12μm: Optimized for thermal imaging, enabling precise detection of heat signatures.

– Durability and Reliability: The mechanical strength of Germanium, combined with AR coatings, ensures long-term reliability even in harsh operating conditions. Its scratch-resistant surface makes it a preferred choice for rugged optical systems.

– Compatibility with Advanced Technologies: Germanium’s compatibility with silicon-based processes allows seamless integration into modern semiconductor and photonics devices, enhancing its versatility.

Applications of Germanium Wafers

The technical characteristics and advantages of Germanium wafers make them suitable for a wide range of applications:

– Thermal Imaging: The 8–12μm AR coating option is specifically designed for thermal cameras, enabling accurate detection of heat signatures in security, firefighting, and industrial inspections.

– Infrared Optics: Germanium’s transparency in the infrared spectrum makes it invaluable for lenses, windows, and filters used in night-vision devices, missile guidance systems, and space exploration equipment.

– Spectroscopy and Sensing: The 3–5μm and 3–12μm coatings cater to applications like gas analysis, pollution monitoring, and chemical detection, where precise wavelength control is essential.

– Rugged Environments: Thanks to its high hardness and durability, Germanium is often used in military and aerospace applications where components must withstand extreme conditions without compromising performance.

Germanium wafers with AR coatings, such as the D55mm wafer with 7–14μm optimization, represent a cutting-edge solution for advanced optical and infrared technologies. Their unique combination of high refractive index, mechanical durability, and enhanced transmission makes them ideal for thermal imaging, spectroscopy, and rugged optics. Despite limitations like thermal runaway and high density, their advantages far outweigh these challenges, especially when properly integrated into system designs. Whether for scientific research, industrial applications, or defense systems, Germanium wafers continue to play a pivotal role in pushing the boundaries of modern technology.

Our Ordering Process

Send us your request with detailed specifications

Receive a commercial offer with terms and costs

After your approval, we handle manufacturing, quality control, and shipping

📦 Shipping

3-5 days in EU, from 10 days to USA

💳 Payment methods

Cash, Bank Transfer, Cards (Visa, Mastercard, Amex, Discover) and PayPal

💬 Questions?

Contact us via WhatsApp, phone, live chat or email