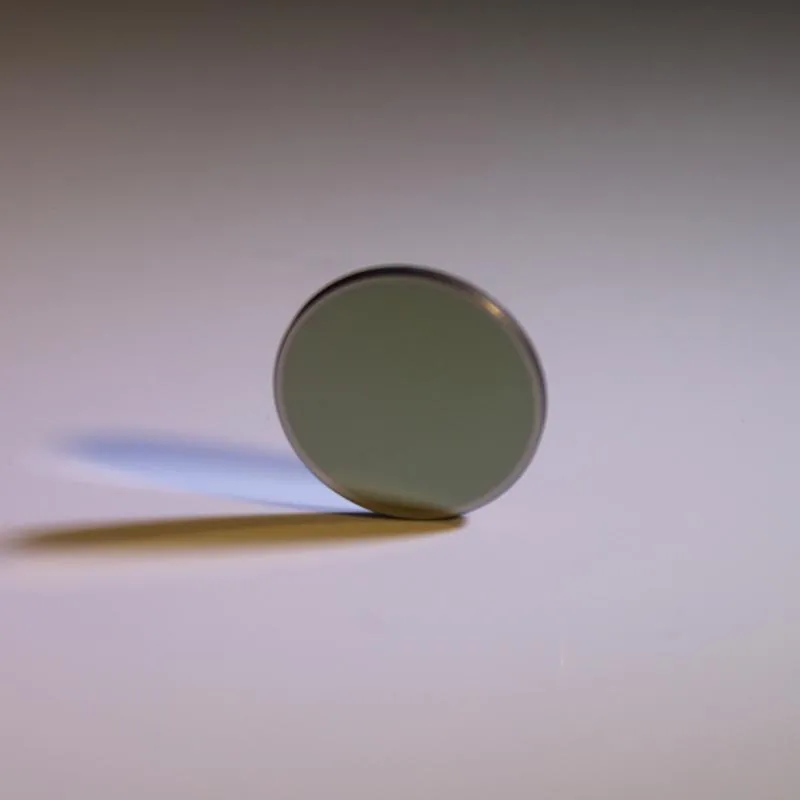

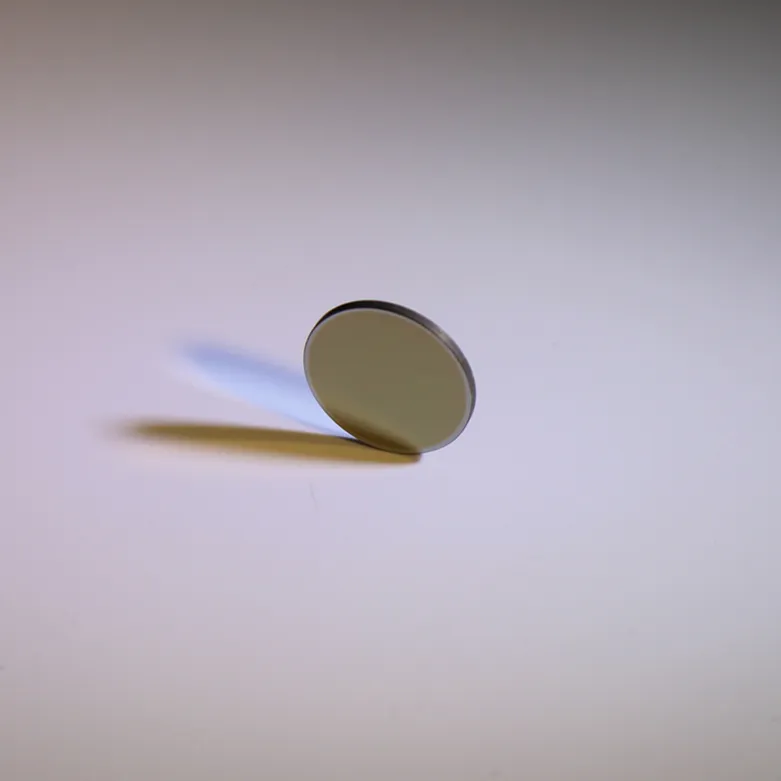

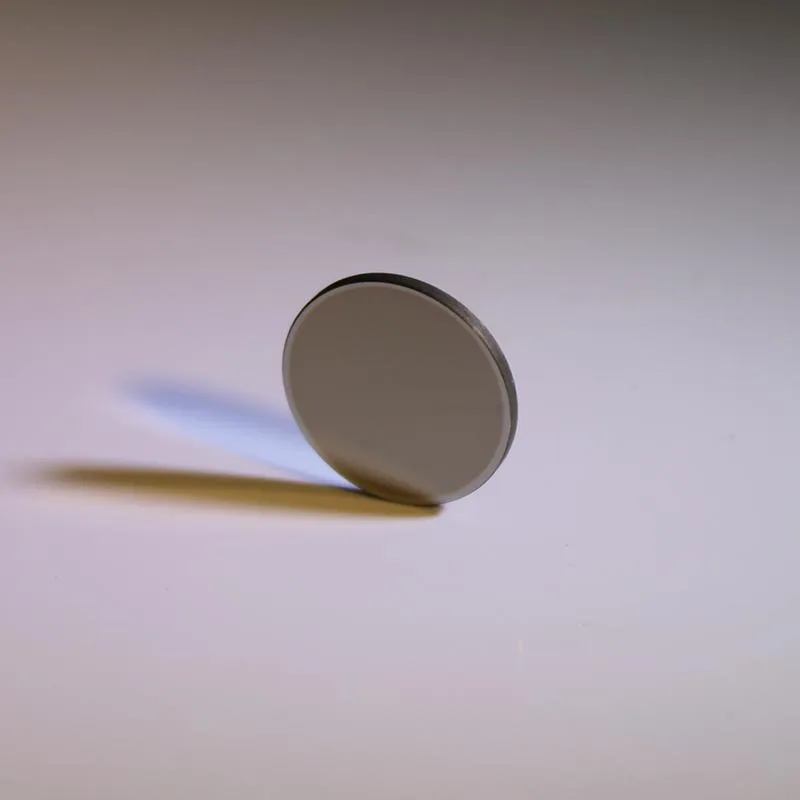

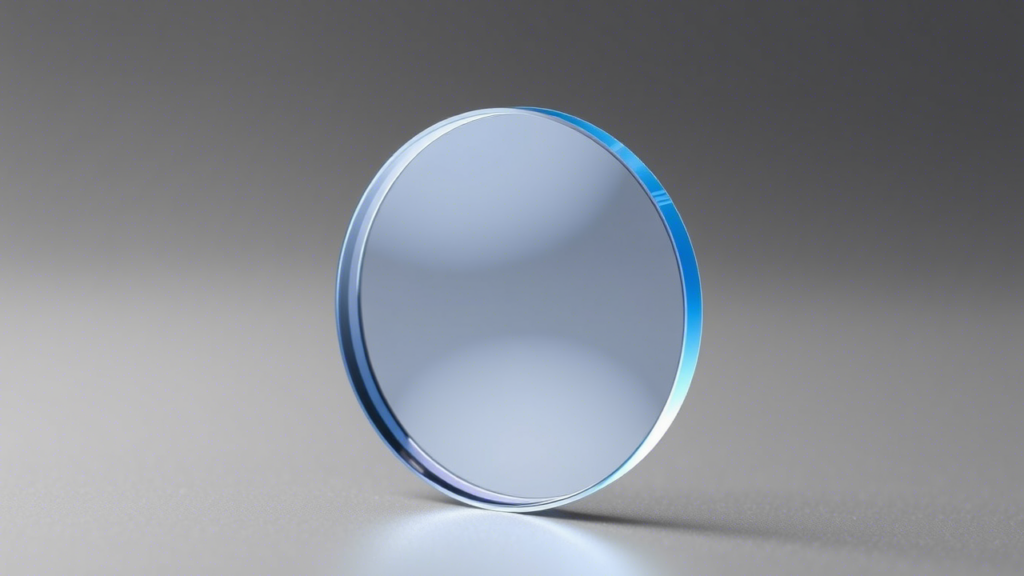

Germanium window for IR 10mm

Dimension: Dia. 45.00mm

Thickness: 2.00mm

Tolerance : +/-0.10mm

Germanium windows are highly specialized optical components widely used in infrared (IR) applications. These windows are crafted from germanium, a metalloid element with the symbol Ge and atomic number 32. Known for its semiconductor properties and grayish-white appearance, pure germanium is chemically similar to silicon and tin. Its unique combination of physical and optical characteristics makes it indispensable in advanced optical systems.

Technical Characteristics of 10mm Germanium Windows

A 10mm thick germanium window is a robust and versatile component designed for demanding infrared applications. Key technical specifications include:

- High Refractive Index: Germanium has a refractive index of approximately 4.0, making it ideal for manipulating infrared wavelengths.

- Anti-Reflection Coating Options: To enhance transmission, these windows come with three AR coating options: 3–5 μm for mid-infrared, 3–12 μm for broadband multispectral use, and 8–12 μm for thermal imaging.

- Transmission Efficiency: When properly coated, germanium windows achieve an average transmission (Tavg) of over 95% within their specified wavelength ranges.

- Thermal Limitations: Germanium is prone to “thermal runaway,” where transmission decreases at higher temperatures. It is recommended to use these windows below 100°C.

- Density and Hardness: With a density of 5.33 g/cm³ and a Knoop hardness of 780, germanium windows are durable yet weighty, requiring careful consideration in weight-sensitive designs.

Applications of Germanium Windows

Germanium windows are extensively used in cutting-edge technologies due to their ability to transmit infrared light efficiently. Some notable applications include:

- Thermal Imaging: Germanium windows are commonly used as front optics in thermal cameras operating in the 8–14 μm range. These cameras are vital for military surveillance, night vision systems, firefighting equipment, and passive thermal imaging.

- Infrared Spectroscopy: Their transparency in the infrared spectrum makes them essential for spectrometers and other analytical instruments requiring sensitive IR detectors.

- Optical Fiber Technology: Germanium dioxide (GeO₂) is used as a dopant in silica fibers, improving their performance without requiring heat treatments that could make them brittle.

- Wide-Angle Lenses: The low optical dispersion and high refractive index of germanium make it suitable for wide-angle lenses in microscopy and advanced camera systems.

PROPERTY OF GERMANIUM

- Clear Aperture (%): 90

- Dimensional Tolerance (mm): 0.0/-0.1

- Coefficient of Thermal Expansion CTE (10⁻⁶/°C): 6.1

- Density (g/cm³): 5.33

- Index of Refraction (nd): 4.002 @ 11µm

- Knoop Hardness (kg/mm²): 780.00

- Parallelism (arcmin): <1

- Poisson’s Ratio: 0.28

- Substrate: Germanium (Ge)

- Surface Quality: 60-40

- Thickness Tolerance (mm): ±0.1

Advantages of Using Germanium Windows

Germanium windows offer numerous advantages that make them a preferred choice for infrared optical systems:

- Superior Infrared Transparency: Germanium’s transparency in the infrared range ensures minimal energy loss during transmission, making it ideal for high-precision applications.

- Enhanced Durability: With a Knoop hardness nearly twice that of magnesium fluoride, germanium windows are highly resistant to scratches and mechanical damage.

- Customizable Coatings: The availability of specialized anti-reflection coatings, such as diamond-like carbon (DLC), ensures optimal performance while providing a rugged surface capable of withstanding harsh environments.

- Versatility: Germanium windows can be tailored for specific wavelength ranges, making them adaptable to a wide array of applications, from thermal imaging to spectroscopy.

Considerations for Design and Use

While germanium windows offer exceptional performance, certain factors must be considered during design and implementation:

- Weight Sensitivity: Due to their high density (5.33 g/cm³), these windows may not be suitable for lightweight systems without proper structural planning.

- Temperature Constraints: Avoid using germanium windows in environments exceeding 100°C, as thermal runaway can significantly reduce their transmission efficiency.

- Environmental Protection: Although diamond-like carbon coatings provide durability, additional protective measures may be necessary in abrasive or corrosive conditions.

Conclusion

Germanium windows, particularly those with a thickness of 10mm, represent a pinnacle of modern optical engineering. Their high refractive index, customizable coatings, and exceptional durability make them indispensable in infrared applications such as thermal imaging, spectroscopy, and optical fiber technology. By understanding their technical characteristics and limitations, engineers and designers can fully leverage the advantages of germanium windows to create innovative and reliable solutions for a wide range of industries.

Our Ordering Process

Send us your request with detailed specifications

Receive a commercial offer with terms and costs

After your approval, we handle manufacturing, quality control, and shipping

📦 Shipping

3-5 days in EU, from 10 days to USA

💳 Payment methods

Cash, Bank Transfer, Cards (Visa, Mastercard, Amex, Discover) and PayPal

💬 Questions?

Contact us via WhatsApp, phone, live chat or email