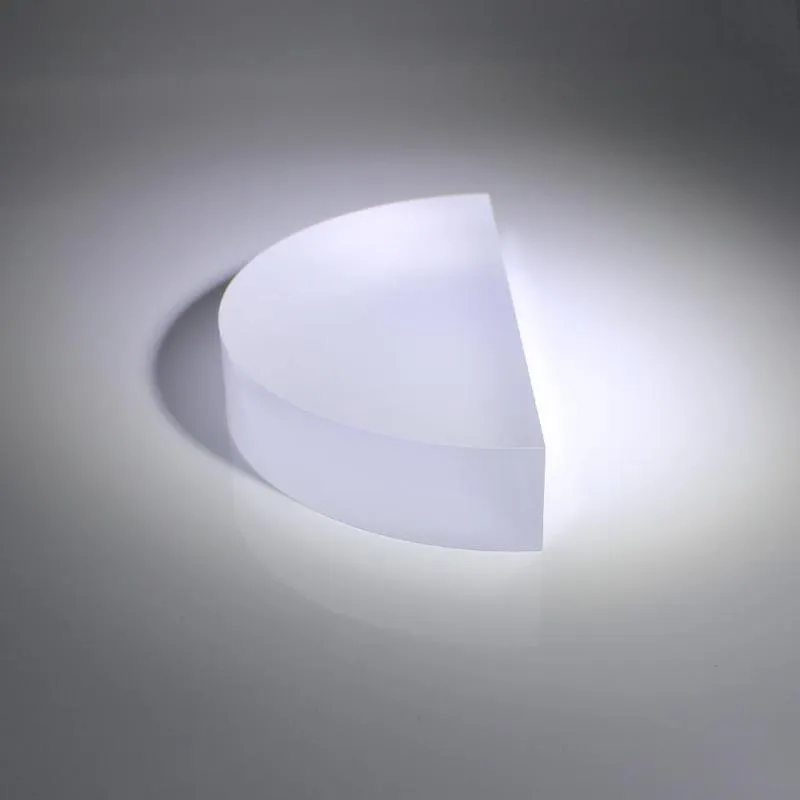

Half Rod Plano Convex Cylindrical Lens

Dimension: 3mm-500mm

Tolerance: +/-0.01mm

Surface Accuracy: lambda/10

Surface Quality: 10-5

Clear Aperature: 95%

Coating: AR @400-700nm, R≤0.5% or Optional

A cylindrical lens or cylinder lens is an optical lens with a cylindrical or semi-cylindrical shape. Like a spherical lens, a cylindrical lens has one curved and one flat side. Unlike a spherical lens, however, cylindrical lenses aren’t fully symmetrical — the orientation of a cylindrical lens affects how it transmits light.

When you’re considering a cylindrical lens versus a spherical lens, the most important distinction is where the lens brings light into focus. A spherical lens brings beams of light to focus at a single point for viewing. A cylindrical lens, by comparison, focuses light onto a line. This change happens because light comes into focus at different points depending on where on the axis it enters the lens. All the focus points line up exactly, producing a horizontal or vertical line of light, depending on the lens orientation.

Through this type of one-dimensional amplification, cylinder lenses effectively correct spherical and chromatic aberrations. As a result, cylindrical lenses are widely used to correct ocular astigmatism and change image size.

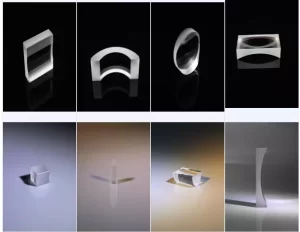

CYLINDRICAL LENS TYPES

PLANO CONVEX CYLINDRICAL LENS

A plano convex cylindrical lens, also known as a positive cylindrical lens, will condense light on one axis. it can be used to magnify an image in one direction, changing the aspect ratio. they will focus collimated light to a line, or to create a line image from a point of light. these lenses are used for such applications as laser projection and illuminating slit and line detector arrays. two plano convex cylindrical lenses can be used to collimate and circularize the light emitted from a laser diode.

A plano convex lens should be oriented so that light is incident on the curved surface if you are focusing to a line. when collimating light, orient your lens so that the light from your line source is incident on the plano surface.

PLANO CONCAVE CYLINDRICAL LENSES

A plano concave cylindrical lenses are called negative cylindrical lenses. they are similar to plano concave lenses, but act only on one axis. they can expand light on this single axis, and diverge collimated input light away from a line. our negative cylindrical lenses can be used for laser line generation, one-dimensional image compression, or anamorphic beam shaping. the curved surface of a negative cylindrical lens should face the source when it is used to diverge a beam, or aberration may become a problem.

ASPHERIC CYLINDRICAL LENS

An aspheric cylindrical lens is to a cylindrical lens what an aspheric lens is to a standard spherical lens. designed to reduce aberration, they provide the same one dimensional focusing a conventional cylindrical lens does. their form is slightly deviated from that of a true cylinder, and they are used in applications similar to those of other cylindrical lenses: anamorphic beam shaping, collimating the output of a laser diode, or focusing a diverging beam on a detector array.

Cylindrical lenses are typically square, circular, or rectangular. VY Optoelectronics Co.,Ltd. manuufacture a line of cylindrical lenses in plano convex cylindrical lens, bi-convex cylindrical lens, plano concave cylindrical lens, bi-concave cylindrical lens, or aspheric cylindrical lenses. Special lenses available on request include parabolic mirrors, cylindrical ellipsoidal mirrors and double curved cylindrical lenses. Off-axis cylindrical mirrors, angled cylindrical mirrors, or fan shaped lenses can also be manufactured to meet a custom order.

Substrate options include Schott or Ohara glass, CDGM, Corning Fused Silica, JGS1 or JGS2. The surface quality of our cylindrical lenses is 20-10 after coating, and the clear aperture is greater than 90 percent of the central dimension.

What Makes Cylindrical Lenses Important?

The main significance of a cylinder lens is its ability to focus light onto a continuous line rather than a fixed point. This quality gives the cylindrical lens various unique abilities, such as laser line generation. Some of these applications simply aren’t possible with a spherical lens. Cylindrical lens capabilities include:

- Correcting astigmatism in imaging systems

- Adjusting the height of an image

- Creating circular, rather than elliptic, laser beams

- Compressing images to one dimension

Cylindrical lenses find use in a wide range of industries. Common applications for cylindrical optical lenses include detector lighting, bar code scanning, spectroscopy, holographic lighting, optical information processing and computer technology. Because applications for these lenses tend to be highly specific, you may need to order custom cylindrical lenses to achieve the desired results.

Cylindrical Lenses for Every Application

Cylinder lenses are optical lenses with different radii on the x and y axis. These lenses are often used to correct for astigmatism in imaging systems, and are also ideal for beam shaping, to adjust image height size, or as a laser line generator. Like spherical lenses, these lenses may have one curved and one flat side or two curved sides. The curved face or faces of a cylindrical lens are portions of a cylinder, and the lens focuses light in a single dimension; i.e., into a line rather than into a point.

As light passes through the face of a cylindrical lens, it travels into a line parallel to the intersection of the surface of the lens and a plane tangent to that. The image is unchanged in the direction of this tangent plane, but is compressed in the direction perpendicular to it.

CYLINDRICAL LENS MANUFACTURING CAPABILITIES OF VY OPTICS

- factory standard

- substrate material: schott, ohara, cdgm, corning fused silica and jgs1, jgs2

- shape: p-concave, p-convex, bi-convex, bi-concave, aspheric or customized

- focal length: +/-1%

- surface quality: 20-10 (after coating)

- surface figure: l/4 @ 633nm

- angle: +/-5″

- clear aperture: >90% of central dimension

| Specifications | Factory Standards | Manufacturing Limit |

| Dimension Tolerance | +/-0.03mm | +/-0.01mm |

| Center Thickness Tolerance | +/-0.03 mm | +/-0.01mm |

| Radius Tolerance | +/-0.3% | +/-0.1% |

| Surface Quality(S/D) | 40-20 | 10-5 |

| Irregularity(Plano Surface) | 1/8Lambda | < 1/15Lambda |

| Irregularity(Cylindrical Surface) | 1/4Lambda | < 1/8Lambda |

| Centration(arc min) | 3′ | 1′ |

Our Ordering Process

Send us your request with detailed specifications

Receive a commercial offer with terms and costs

After your approval, we handle manufacturing, quality control, and shipping

📦 Shipping

3-5 days in EU, from 10 days to USA

💳 Payment methods

Cash, Bank Transfer, Cards (Visa, Mastercard, Amex, Discover) and PayPal

💬 Questions?

Contact us via WhatsApp, phone, live chat or email