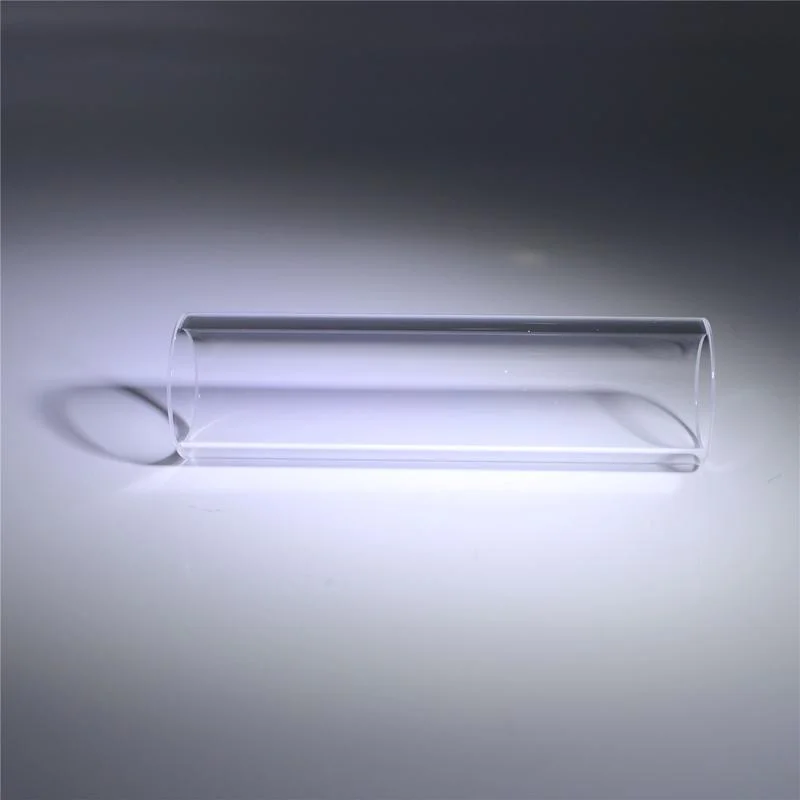

JGS-2 Quartz Glass Tube

Dimension: 3.00mm-380.00mmm

Tolerance: +/-0.1mm

Surface Accuracy: As requested

Surface Quality: 60/40

Clear Aperature: 95%

Coating: Optional

JGS-2 (UV optical quartz glass). It is an optical quartz glass made by oxyhydrogen flame melting and is suggested for applications in the wavelength range of 220-2500 nm!

APPLICATIONS OF QUARTZ TUBES

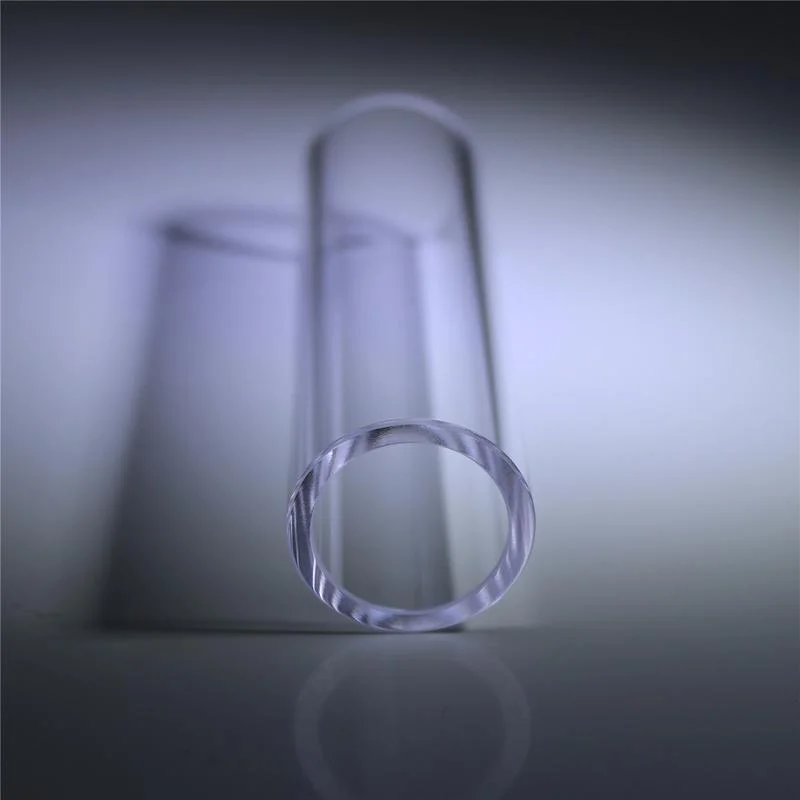

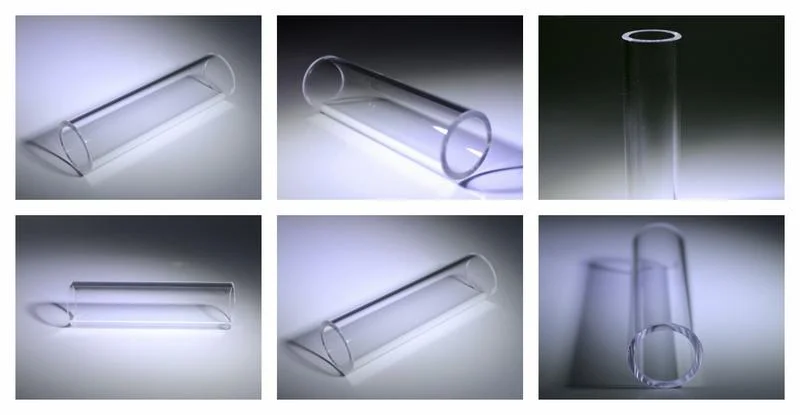

Quartz glass tube are engineered to optimize performance or economy for specific applications. Our quartz tubes are available in clear fused quartz glass as well as fused silica。

Our company produce a wide range of dimensions for applications such as general lighting, laser flash lamps, digital projection, semiconductor (lithography/cleaning), and UV curing. Materials are available as standard stock items or custom fabrication with precision accuracy.

Besides lamp applications, VY could provide you with precision glass tube and glass rod for medical, electronic, and optical communications, as well as scientific applications. We have different grade of material choice for you, which could meet your vaerious demands, whether performance or economy.

SPECIFICATIONS OF OUR QUARTZ TUBES

|

Material |

Quartz glass, fused silica, JGS1, JGS2, JGS3 etc.. |

|

Dimension Tolerance |

+0.0/0.1mm |

|

Thickness tolerance |

+/-0.1mm |

|

Surface Quality |

80/50——20/10 |

| Coating |

Optional |

HOW ARE QUARTZ TUBES MADE?

This is the most common method used to produce quartz glass in a continuous process. The quartz sand is melted in a tungsten crucible that contains electrical heating elements; the fused material flows down from the crucible through a bottom mould where it is shaped into tubes, plates and rods.

PROPERTIES OF QUARTZ GLASS:

- Extreme wide spectral transmission range from deep UV to middle IR.

- High optical transmission and low optical absorption.

- Low variation and disturbance of the refractive index in one solid piece and optical homogeneity from one melt to the next.

- High resistance to high intensity laser radiation, which also applies to the UV spectral range (e.g. excimer laser).

- High application temperature 1200 degrees C — almost four times higher than ordinary glass.

- Low thermal expansion coefficient resulting in an extremely high temperature shock resistance allowing rapid heating & cooling.

Our Ordering Process

Send us your request with detailed specifications

Receive a commercial offer with terms and costs

After your approval, we handle manufacturing, quality control, and shipping

📦 Shipping

3-5 days in EU, from 10 days to USA

💳 Payment methods

Cash, Bank Transfer, Cards (Visa, Mastercard, Amex, Discover) and PayPal

💬 Questions?

Contact us via WhatsApp, phone, live chat or email