Quartz Materials

Melting point, °C: 1467

Thermal conductivity, W/(m x K) (T = 25°C): 10.7 (parallel to axis Z)/6.2 (perpendicular to axis Z)

Shear modulus (G), GPa: 31.14

Bulk modulus (K), GPa: 36.4

Quartz, a highly significant piezoelectric material, is currently the most widely used crystal and a crucial electronic material. Although it shares the same chemical composition as silicon dioxide (SiO2), crystal quartz differs from fused quartz and fused silica, which lack orientation as they are not crystalline materials.

Crystal quartz has a single crystal structure formed by a hexagonal system of 32 point groups, reflecting its symmetrical shape on a macroscopic scale. Quartz crystals exhibit birefringence, but this phenomenon does not occur when light enters along the Z-axis, which is thus known as the optical axis of quartz.

When subjected to an electric field, the crystal generates stress and deforms, leading to mechanical vibrations and producing a specific frequency. Quartz crystal resonators are manufactured by leveraging these inverse piezoelectric effect characteristics. Depending on the cut angle, quartz commonly exhibits various vibration modes: length extensional vibration, flexural vibration, face shear vibration, and thickness shear vibration.

Hydrothermal Growth of Quartz:

- The autoclave is filled to some predetermined factor with water plus mineralizer (NaOH or Na2CO3).

- The baffle localizes the temperature gradient so that each zone is nearly isothermal.

- The seeds are thin slices of (usually) Z-cut single crystals.

- The nutrient consists of small (~2½ to 4 cm) pieces of single-crystal quartz (“lascas”).

- The temperatures and pressures are typically about 3500C and 800 to 2,000 atmospheres; T2 – T1 is typically 40C to 100C.

- The nutrient dissolves slowly (30 to 260 days per run), diffuses to the growth zone, and deposits onto the seeds.

1.Physical properties of synthetic crystal quartz

| Density, g/cm3 | 2.65 |

| Melting point, °C | 1467 |

| Thermal conductivity, W/(m x K) (T = 25°C) | 10.7 (parallel to axis Z) 6.2 (perpendicular to axis Z) |

| Thermal coefficient of linear expansion at temperature range 0-25°Ñ, °C-1 | 7.1 õ 10-6 (parallel to axis Z) |

| 13.2 õ 10-6 (perpendicular to axis Z) | |

| Hardness (Mohs) | 7 |

| Specific heat capacity, J/(kg x K) (T = 25°C) | 710 |

| Dielectric constant at 30 MHz | 4.34 (parallel to axis Z) 4.27 (perpendicular to axis Z) |

| Young’s modulus (E), GPa | 97.2 (parallel to axis Z) 76.5 (perpendicular to axis Z) |

| Shear modulus (G), GPa | 31.14 |

| Bulk modulus (K), GPa | 36.4 |

| Chemical stability | insoluble in water |

| Elastic coefficients | C11=87 C12=7 C44=58 C13=13 C14=18 C33=106 |

2.Synthetic crystal quartz refractive index vs wavelength

| l, mm | n0 | ne | l, mm | n0 | ne | l, mm | n0 | ne |

| 0.185 | 1.676 | 1.69 | 0.243 | 1.605 | 1.617 | 0.589 | 1.544 | 1.553 |

| 0.194 | 1.66 | 1.673 | 0.263 | 1.593 | 1.604 | 1.083 | 1.534 | 1.543 |

| 0.204 | 1.643 | 1.656 | 0.291 | 1.581 | 1.591 | 1.8 | 1.524 | 1.532 |

| 0.219 | 1.625 | 1.637 | 0.34 | 1.567 | 1.577 | 2.5 | 1.512 | 1.52 |

| 0.231 | 1.614 | 1.626 | 0.405 | 1.557 | 1.567 | 3 | 1.5 | 1.507 |

3.Quality evaluation of synthetic quartz crystal

a) The amount of crystal defect and impurity in synthetic quartz crystal depends on growth rate, mineralizer and raw material. The growth rate affects greatly to the important properties such as infra-red absorption coefficient α, which correlates to Q value, and frequency –temperature characteristics. The larger growth rate causes increase in α, decrease in Q value, and dispersion in frequency-temperature characteristics.

b) The quality index of synthetic quartz crystal was originally a Q value, and a 5 MHz quartz crystal unit operated in 5th overtone mode was used to obtain the Q value. But it required laborious work to fabricate the 5 MHz crystal unit, so the index had been changed to the coefficient α instead of the Q value.

4.Standard specification for synthetic quartz crystal

a) Twinning: There shall be no electrical or optical twinning in the usable region.

b) Strain: There shall be no strain contained both inside and surface of seed crystal as well as in a grown quartz crystal.

c) Cracks and fractures: There shall be no cracks, chippings or fractures in the usable region.

d) Inclusion density: The specification is in accordance with the IEC 60758.

| Size range | Qty per cm3 | |||

| Grade (µm) | 10 to 30 | 30 to 70 | 70 to 100 | >100 |

| Ia | 2 | 1 | 0 | 0 |

| Ib | 3 | 2 | 1 | 1 |

| I | 6 | 4 | 2 | 2 |

| II | 9 | 5 | 4 | 3 |

| III | 12 | 8 | 6 | 4 |

e) Infra-red quality indication: The specification is in accordance with the IEC 60758.

| Grade | Max. α3585 | Estimated Q values (x 106) |

| A | 0.015 | 3.8 |

| A | 0.024 | 3 |

| B | 0.05 | 2.4 |

| C | 0.069 | 1.8 |

| D | 0.1 | 1.4 |

f) Etch channel density: The specification is in accordance with the IEC 60758.

| Grade | Max. number per cm3 |

| 1 | 10 |

| 2 | 30 |

| 3 | 100 |

| 4 | 300 |

| 5 | 600 |

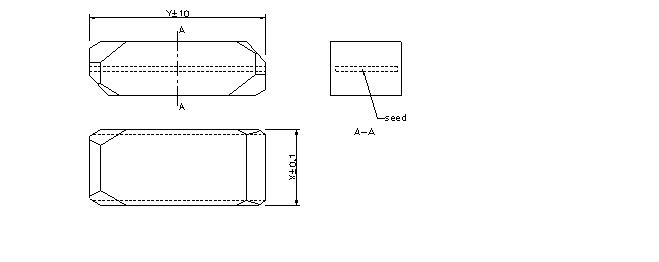

5.Specification for lumbered quartz crystal

a) Angles:

i. Rotation angle of X-surface around Y-axis: 00°00’±15’

ii. Rotation angle of X-surface around Z-axis: 00°00’±15’

b) Dimensional tolerance:

i. Along X or Z axis:±0.1 mm

ii. Along Y axis:±10 mm

c)Surface roughness: as customized, lapped and polished are both available.

Our Ordering Process

Send us your request with detailed specifications

Receive a commercial offer with terms and costs

After your approval, we handle manufacturing, quality control, and shipping

📦 Shipping

3-5 days in EU, from 10 days to USA

💳 Payment methods

Cash, Bank Transfer, Cards (Visa, Mastercard, Amex, Discover) and PayPal

💬 Questions?

Contact us via WhatsApp, phone, live chat or email