Quartz Plate with Golden Coating oval shape

- Length: 5mm-1500mm

Round Quartz Glass Plate/Sheet:

- Diameter: 5mm-1500mm

- Thickness: 0.5mm-100mm

Understanding Quartz Plates with Golden Coating

Quartz plates with golden coating are advanced optical components designed to deliver exceptional performance in a variety of industrial and scientific applications. These plates combine the natural properties of high-purity quartz with the added benefits of a reflective golden layer, making them ideal for environments requiring heat resistance, chemical stability, and high optical transmittance.

Technical Specifications of Quartz Plates

Quartz plates are crafted from premium-grade quartz materials, ensuring a silica content exceeding 99.99%. Their technical properties make them highly reliable under extreme conditions:

- High-Temperature Resistance: Capable of enduring temperatures up to 1100°C in short-term use, with excellent thermal shock resistance.

- Low Thermal Expansion: The coefficient of thermal expansion is exceptionally low (~5.5 x 10⁻⁷/°C), minimizing deformation during temperature fluctuations.

- Chemical Stability: Resistant to acids (except hydrofluoric acid) and alkalis, ensuring durability in corrosive environments.

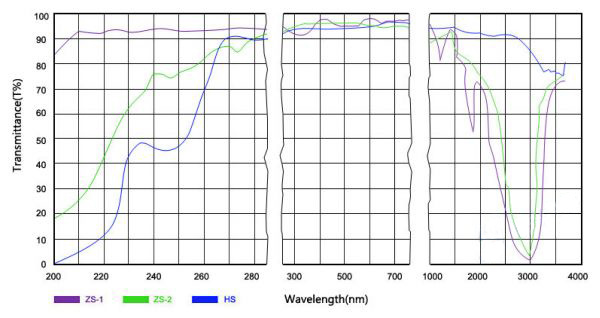

- Optical Transmittance: High transparency across ultraviolet (UV), visible, and infrared (IR) wavelengths, depending on the quartz grade.

- Mechanical Strength: With a Mohs hardness of 7, these plates are highly resistant to scratches and mechanical damage.

Benefits of Quartz Plates with Golden Coating

The addition of a golden coating enhances the functionality of quartz plates, offering several advantages:

- Enhanced Reflectivity: The golden layer improves reflectivity, making these plates suitable for applications like solar energy systems and optical devices.

- Heat Management: The coating reflects heat effectively, reducing thermal stress and improving the longevity of the plate.

- Corrosion Protection: The combination of quartz’s natural chemical stability and the protective golden layer ensures superior resistance to harsh environments.

- Precision Performance: Strict manufacturing controls ensure no air bubbles or lines, providing flawless optical clarity and structural integrity.

- Versatility: Available in different grades (JGS1, JGS2, JGS3) tailored for specific wavelength ranges, from far ultraviolet to infrared applications.

Applications of Quartz Plates with Golden Coating

These versatile plates are widely used across various industries due to their unique properties:

- Electric Light Sources: Ideal for high-intensity lighting systems that require thermal and UV resistance.

- Semiconductor Manufacturing: Used in photolithography and other processes demanding high purity and precision.

- Solar Energy Systems: Enhances efficiency by reflecting unused light back into the system, maximizing energy capture.

- Optical Communications: Ensures reliable signal transmission in fiber optic networks.

- Military and Aerospace: Provides robust performance in harsh environments, including high temperatures and radiation exposure.

- Metallurgy and Chemical Industries: Resists chemical corrosion and thermal shock, making it suitable for industrial furnaces and reactors.

- Environmental Protection: Used in equipment for monitoring and controlling pollution levels.

Customization Options

We offer tailored solutions to meet the specific needs of our clients:

- Material Selection: Choose from three types of quartz slabs based on application requirements:

- JGS1: Optimized for far ultraviolet applications.

- JGS2: Designed for ultraviolet optics.

- JGS3: Tailored for infrared applications.

- Precision Control: Strict adherence to size and tolerance specifications ensures seamless integration into your systems.

- Defect-Free Quality: Our manufacturing process eliminates air bubbles and air lines, ensuring optical clarity and structural integrity.

- Professional Inspection: Each plate undergoes rigorous testing before delivery to guarantee compliance with industry standards.

Physical Properties Table

| Property | Value |

|---|---|

| Silica Content | >99.99% |

| Mohs Hardness | 7 |

| Maximum Operating Temperature | Up to 1100°C (short-term) |

| Thermal Expansion Coefficient | Extremely low (~5.5 x 10⁻⁷/°C) |

| Electrical Insulation | Excellent dielectric strength |

Conclusion

Quartz plates with golden coating are a testament to cutting-edge engineering, offering unmatched performance in demanding applications. Their ability to withstand high temperatures, resist chemical corrosion, and provide superior optical transmittance makes them indispensable in industries ranging from semiconductors to solar energy systems. With customizable options and stringent quality control, our quartz plates ensure reliability and precision in every application. Whether you need a solution for thermal management, optical enhancement, or chemical resistance, these plates deliver exceptional results, making them a cornerstone of modern technology.

Spectrogram of JGS1, JGS2, JGS3:

Our Ordering Process

Send us your request with detailed specifications

Receive a commercial offer with terms and costs

After your approval, we handle manufacturing, quality control, and shipping

📦 Shipping

3-5 days in EU, from 10 days to USA

💳 Payment methods

Cash, Bank Transfer, Cards (Visa, Mastercard, Amex, Discover) and PayPal

💬 Questions?

Contact us via WhatsApp, phone, live chat or email