Sapphire glass rod

Dimension: 1.0mm-460mm

Thickness: 0.1mm-30mm

Surface Accuracy: lambda/20

Surface Quality: 10-5

Tolerance: +/-0.01mm

Parallelism: 30"

What is sapphire crystal?

Sapphire crystal (Al2O3) is an excellent substrate for a range of rugged applications.

It has high transmission from 150nm up to around 5µm therefore ideal for UV, Visible and IR applications. Sapphire lenses have excellent mechanical strength and hardness. With sapphire having superb thermal and chemical resistance and being scratch resistant, sapphire is a perfect choice for lens applications . Sapphire is inert and resistant to attack from most processing environments, such as hydrofluoric acid.

We are supply a range of sapphire components, such as sapphire lens, sapphire flat, sapphire window, sapphire dome, sapphire ball lens, sapphire prism, sapphire rod, sapphire tube, etc. Our sapphire lens can also be antireflective coated to increase efficiency in UV and IR applications.

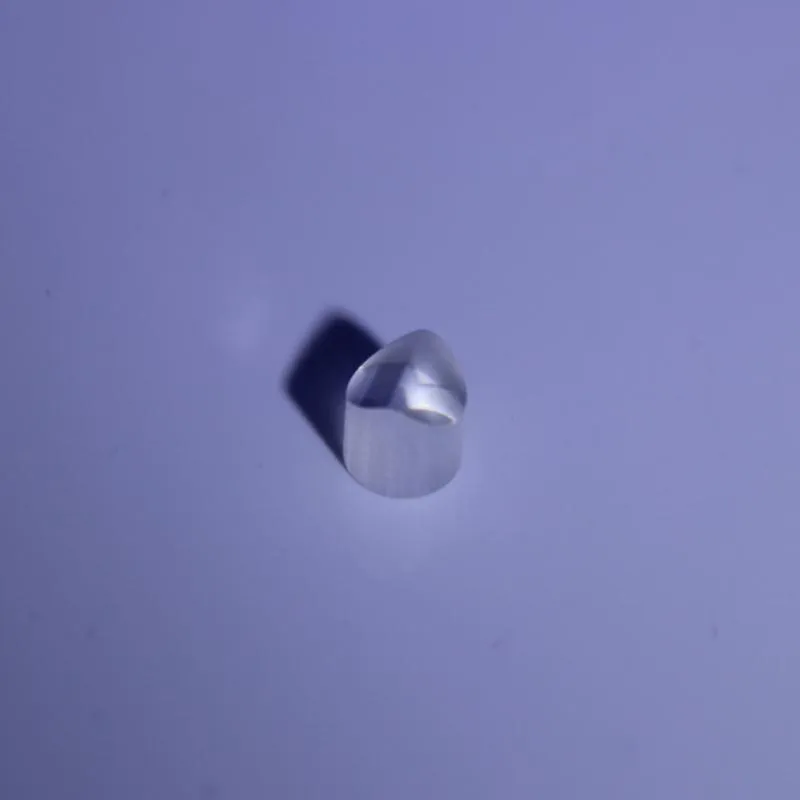

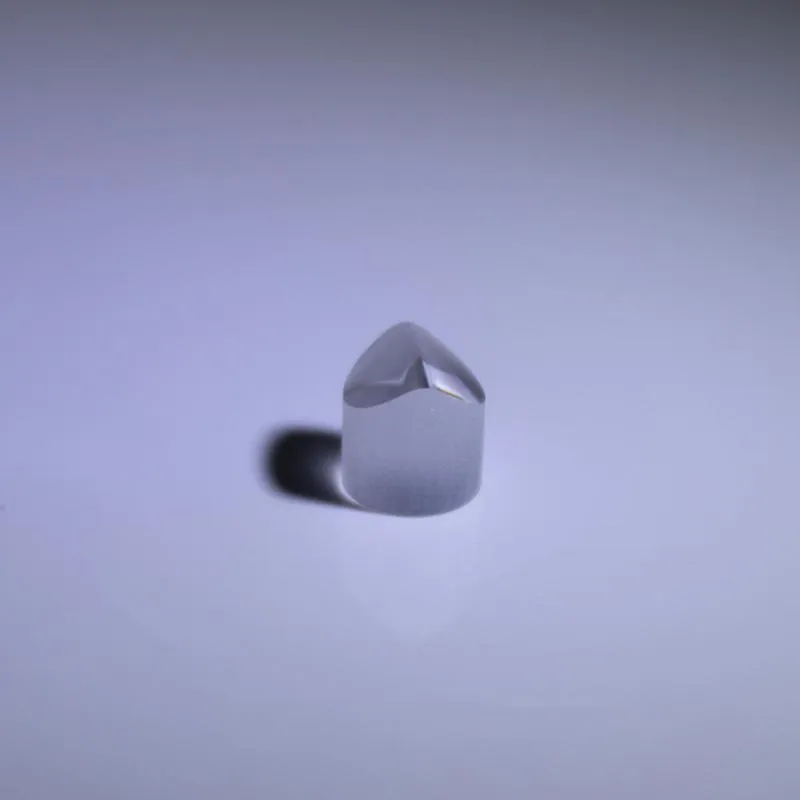

(Picture show of our sapphire glass rod lenses)

Why choose a sapphire material?

Maybe you will find that when the project is complicated or the product quality requirements are relatively high, people often choose sapphire, this benefits from the unique features and benefits as follow:

• Withstands temperatures up to 2000°C

• Transmits in the UV-visible-IR wavelengths

• Significant Abrasion Resistance: 2nd in hardness to diamond

• Chemically inert and insoluble (Biocompatible material)

• High thermal conductivity

• Complex shapes through machining, bonding, lamination

The key benefits of sapphire cone are:

Very wide optical transmission band from UV to near-infrared, (0.15–5.5 µm)

Significantly stronger than other optical materials or standard glass

Highly resistant to scratching and abrasion (9 on the Mohs scale of mineral hardness scale, the 3rd hardest natural substance next to moissanite and diamonds)

Extremely high melting temperature (2030 °C)

Specifications of our sapphire cones

Common specification of our sapphire cones as follow:

| Material | Sapphire |

| Surface quality | 80-50 to 10-5 Scratch/Dig |

| Surface flatness | <lambda to lambda/20 |

| Parallelism | <=1min — 2sec |

| Clear Apenture | 80% — 100% |

Our Ordering Process

Send us your request with detailed specifications

Receive a commercial offer with terms and costs

After your approval, we handle manufacturing, quality control, and shipping

📦 Shipping

3-5 days in EU, from 10 days to USA

💳 Payment methods

Cash, Bank Transfer, Cards (Visa, Mastercard, Amex, Discover) and PayPal

💬 Questions?

Contact us via WhatsApp, phone, live chat or email