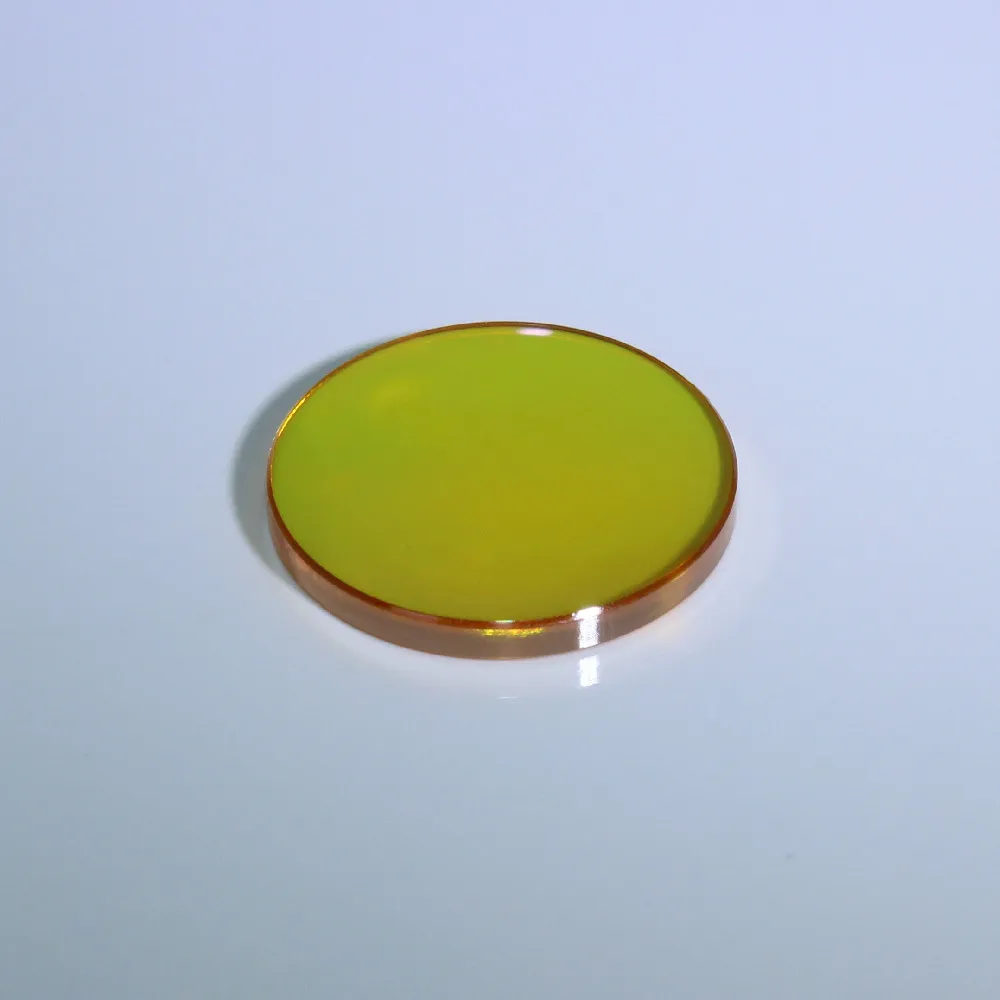

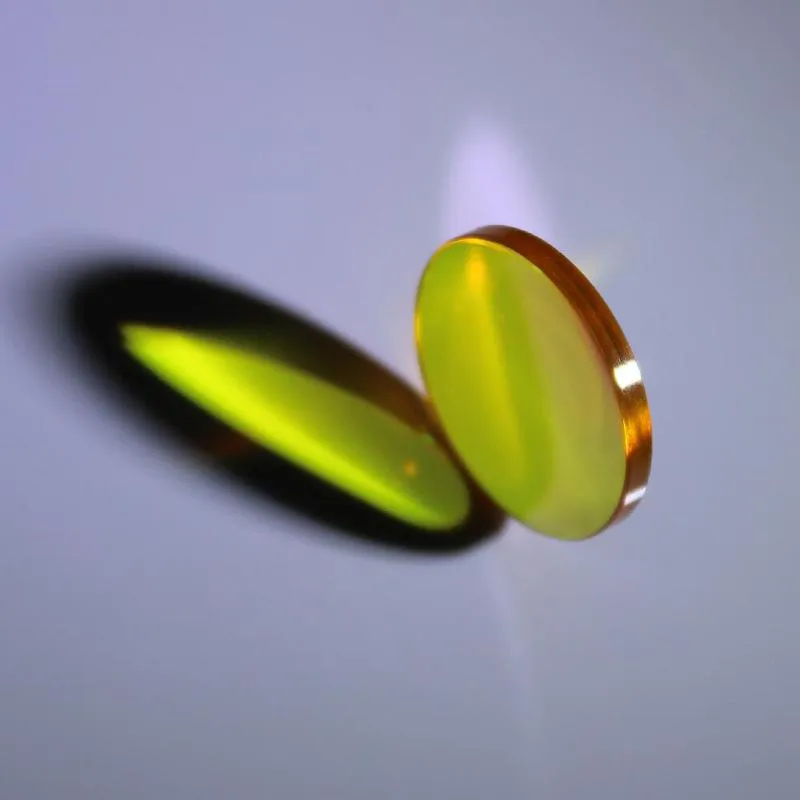

ZnSe Lens

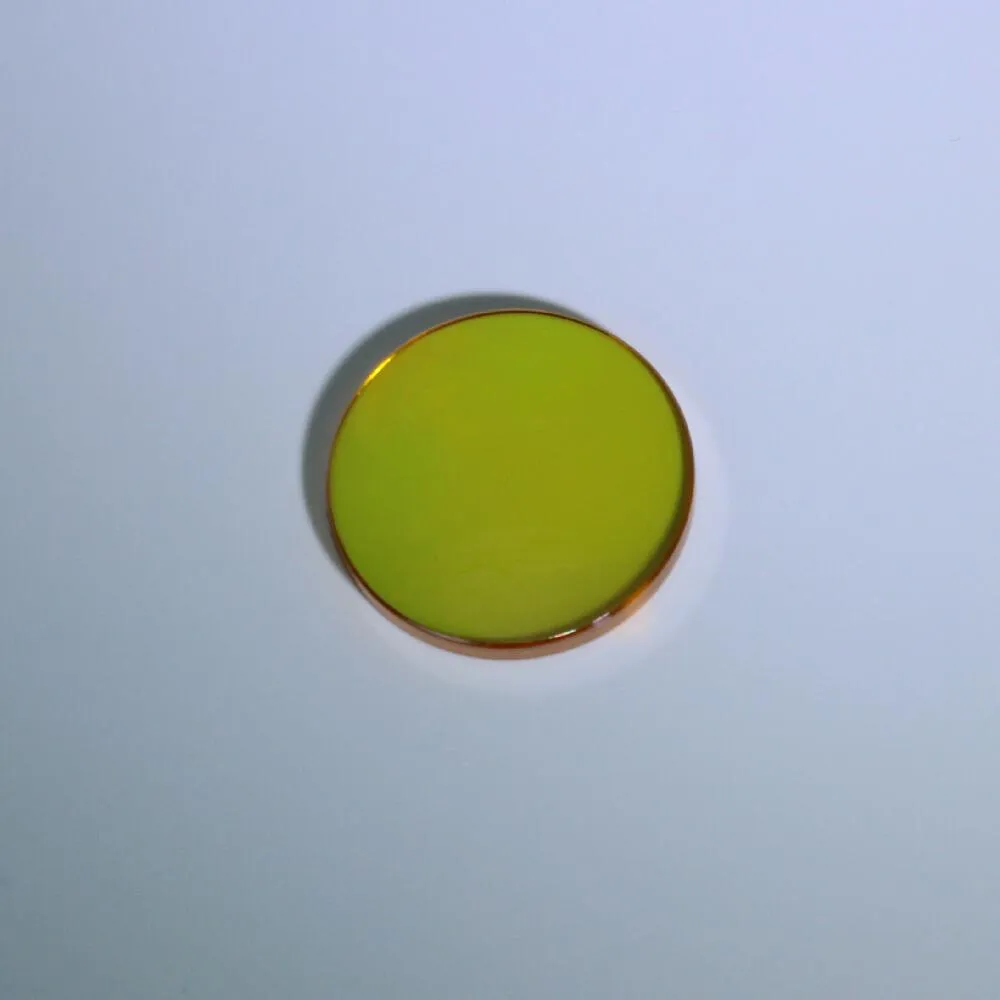

Dimension: Dia. 25.00mm

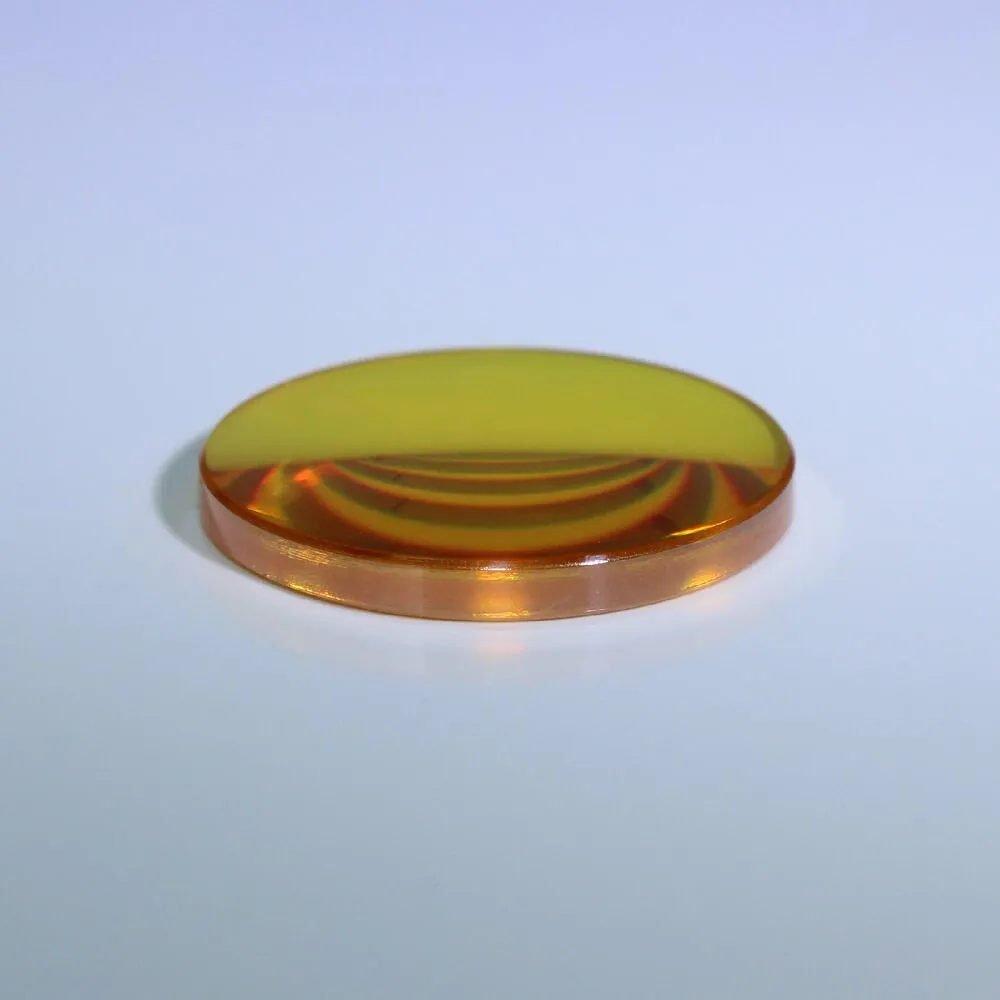

Thickness: 1.00mm

Tolerance : +/-0.10mm

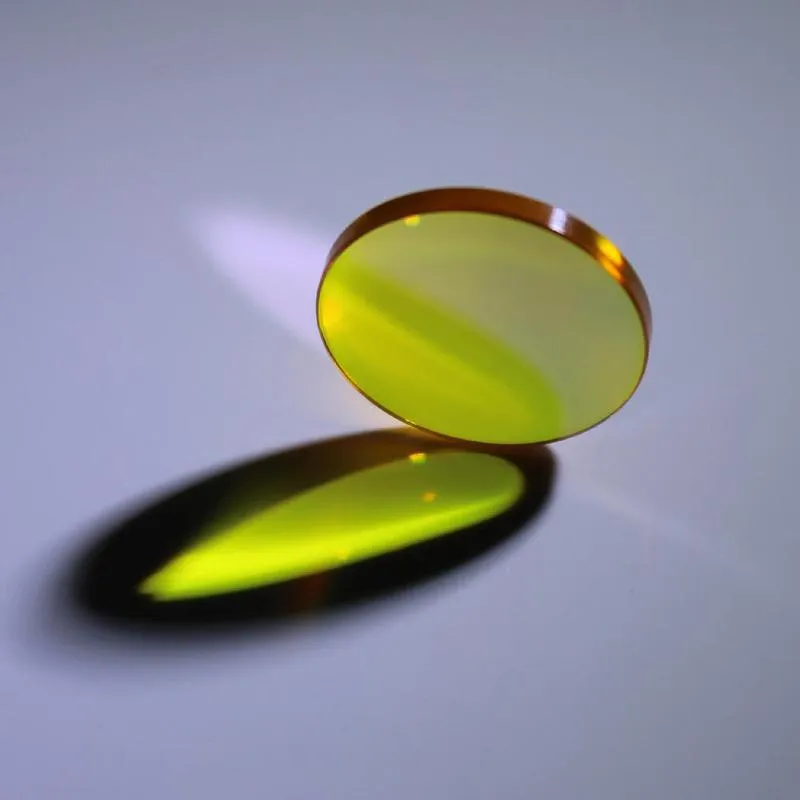

Zinc Selenide (ZnSe) lenses are highly specialized optical components widely used in thermal imaging, high-power CO2 laser systems, and life sciences. These lenses are crafted from a transparent, yellowish polycrystalline material that transmits light across a broad spectrum, ranging from visible wavelengths to mid-infrared (0.5–21 µm). This unique transmission range makes ZnSe lenses ideal for applications requiring both infrared functionality and occasional visual inspection.

Key Technical Characteristics of ZnSe Lenses

ZnSe lenses possess several technical properties that make them indispensable in precision optics:

- Transmission Range: ZnSe lenses transmit light between 0.5 µm and 21 µm, covering the visible and mid-infrared spectra. This versatility ensures their suitability for diverse applications.

- Low Absorption Coefficient: With an absorption coefficient of just 0.0005 cm⁻¹ at 10.6 µm, ZnSe lenses exhibit minimal energy loss, making them ideal for high-precision laser systems.

- Thermal Stability: ZnSe has a melting point of 1525°C and a thermal conductivity of 18 W m⁻¹ K⁻¹ at 298K. Its low thermal expansion coefficient (7.1 × 10⁻⁶ /°C) ensures excellent resistance to thermal shock, allowing these lenses to perform reliably in demanding environments.

- Reflectivity and Coatings: The reflectivity of ZnSe is approximately 29.1% at 10.6 µm for two surfaces. Anti-reflection (AR) coatings can reduce this further, ensuring minimal energy loss during operation.

- Refractive Index: ZnSe has a refractive index of about 2.67 at 550 nm (green) and 2.40 at 10.6 µm (LWIR), enabling precise focusing and high optical performance.

Advantages of ZnSe Lenses

The unique properties of ZnSe lenses provide numerous advantages for advanced optical systems:

- Broad Spectral Transmission: The ability to transmit both visible and infrared light makes ZnSe lenses suitable for applications requiring dual functionality, such as thermal imaging with visual inspection capabilities.

- Energy Efficiency: Ultra-low absorption (<0.3%) minimizes energy loss, enhancing the efficiency of high-power CO2 laser systems.

- Durability: High resistance to thermal shock allows ZnSe lenses to withstand extreme temperature variations, making them ideal for thermally demanding environments.

- Customizability: ZnSe lenses can be coated with anti-reflection layers or tailored into various shapes, including spherical, cylindrical, and aspheric designs, to meet specific application requirements.

- High Precision: Rigorous manufacturing processes ensure exceptional surface quality and dimensional accuracy, meeting the strictest industry standards.

Manufacturing Process of ZnSe Lenses

The production of ZnSe lenses involves several precision steps to ensure superior quality:

- Material Selection: High-quality ZnSe blanks are produced using chemical vapor deposition (CVD), ensuring the highest purity and consistency.

- Diamond Turning: The blanks are precisely shaped using diamond turning techniques to achieve the desired curvature, roughness, and dimensions.

- Polishing: The lens surfaces are polished to meet stringent optical standards, ensuring clarity and minimal distortion.

- Coating Application: Anti-reflection or other custom coatings can be applied to enhance performance for specific wavelengths, such as 10.6 µm for CO2 lasers.

- Quality Testing: Each lens undergoes rigorous testing using state-of-the-art metrology equipment to verify compliance with specifications and industry standards.

Technical Specifications Table

| Parameter | Specification |

|---|---|

| Substrate Material | ZnSe |

| Shape | Spherical Plano-Concave, P-Convex, Concave-Convex, or Aspheric |

| Surface Figure | λ/10 or better before coating at 10.6 μm |

| Surface Quality | 40-20 or better per MIL-PRF-13830B |

| Dimensional Tolerance | + 0.00mm, – 0.25mm |

| Thickness Tolerance | +/- 0.25mm |

| Chamfer | 0.35mm at 45° (typical) |

| Concentricity | < 0.05mm |

| Focal Length Tolerance | +/- 2% |

| Antireflection Coating | Ravg < 0.6% per surface at 3-5μm Ravg < 0.75% per surface at 8-12μm Ravg < 0.5% per surface at 10.6μm |

| Clear Aperture | Exceeds central 85% of dimension |

| Absorption | <0.3% total absorption as measured by CO2 laser calorimetry |

| Design Wavelength | 10.6μm |

Applications of ZnSe Lenses

ZnSe lenses are widely used in various industries due to their exceptional optical properties:

- Thermal Imaging: Ideal for detecting heat signatures in military, medical, and industrial applications.

- CO2 Laser Systems: Used in cutting, welding, and engraving processes due to their low absorption and high precision.

- Life Sciences: Employed in spectroscopy and microscopy for analyzing biological samples.

- Infrared Optics: Serve as critical components in infrared cameras and sensors.

- Scintillators: ZnSe doped with tellurium (ZnSe(Te)) is used in x-ray and gamma-ray detectors, offering a scintillation peak at 640 nm.

ZnSe lenses are a cornerstone of modern optical technology, offering unparalleled performance in thermal imaging, laser systems, and beyond. Their broad spectral transmission, low absorption, and thermal stability make them indispensable in demanding applications. Whether you need a standard lens or a custom-designed solution, ZnSe lenses provide the precision and reliability required for cutting-edge innovations. With over a decade of expertise in crafting high-quality ZnSe lenses, we ensure competitive pricing and exceptional service, empowering your projects with the best optical solutions available.

Our Ordering Process

Send us your request with detailed specifications

Receive a commercial offer with terms and costs

After your approval, we handle manufacturing, quality control, and shipping

📦 Shipping

3-5 days in EU, from 10 days to USA

💳 Payment methods

Cash, Bank Transfer, Cards (Visa, Mastercard, Amex, Discover) and PayPal

💬 Questions?

Contact us via WhatsApp, phone, live chat or email